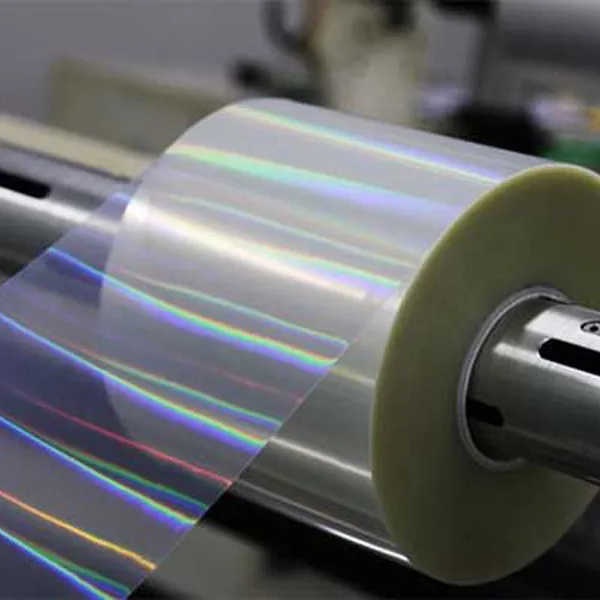

PET plastic rolls production line adopts advanced extrusion-cooling-stretching process.

PET plastic sheet is a thermoplastic environmentally friendly plastic product, which is odorless and tasteless after burning, and does not produce toxic gas.

Food-grade plastics are all materials that meet the national food safety requirements and will not produce toxic substances during use.

Blister is a production process in which PP, PET, PS and other plastic sheets are heated at high temperature and vacuum formed on the mold. Blister packaging is a general term for plastic products manufactured by the blister process, and the molded produc

Anti -ultraviolet PET plastic sheet can block ultraviolet light, avoid damage, and extend the service life. Widely used in the packaging of cosmetics, food, electronics, toys, toys...

The polyester sheet series includes PETG, APET, CPET, etc., which are new sheet products developed and developed rapidly in recent years.

These include PP natural color, PP natural color transparent, PP high transparent plastic sheet and PP sheet in other colors. The characteristics of the products produced by each PP material are different, and the uses are also different

Sprite's current plastic packaging contains green polyethylene terephthalate (PET), removing color from bottles can improve the quality of recycled materials, after recycling, clear PET Sprite bottles can be remade into bottles, help drive a circular eco

With the help of the KHS Group, Eckes-Granini is making its packaging portfolio more environmentally friendly. Since mid-May 2021, its 1L hohes C juice bottle has been made entirely of recycled plastic (rPET).

Since 2018, the German company Eckes-Grani

Store High impact polystyrene (HIPS) plastic rolls in a cool, dry environment. Avoid exposure to direct sunlight or heat, as prolonged exposure can cause the material to degrade.