Material Composition:

HIPS PlasticPrice Range:

$1.28-$1.99Eco-Friendly HIPS Plastic Rolls provide an ideal balance between sustainability, durability, and versatility, making them a preferred choice in packaging, electronics, food trays, and consumer goods manufacturing.

In today’s global market, manufacturers and packaging companies are under increasing pressure to choose materials that are not only cost-effective but also environmentally responsible.

As sustainability becomes a central purchasing decision, Eco-Friendly HIPS Plastic Rolls have emerged as one of the most reliable and versatile materials for a wide range of thermoforming and packaging applications.

These rolls offer an ideal balance of environmental benefits, performance consistency, and operational efficiency, making them the preferred choice for industries such as food packaging, electronics, cosmetics, medical devices, and consumer goods.

Eco-Friendly HIPS Plastic Rolls are environmentally responsible plastic sheet rolls made from High Impact Polystyrene (HIPS) — a lightweight, durable, and easily recyclable thermoplastic. These rolls are designed to offer excellent impact resistance, superior thermoforming performance, and high stability while reducing environmental impact compared to conventional plastic materials.

HIPS plastic roll is known for being easy to form, safe, and affordable, making it a popular material for manufacturing food trays, electronic packaging, cosmetic blister packs, medical packaging, and various consumer goods. When produced using eco-friendly materials and sustainable manufacturing processes, HIPS becomes a greener alternative for companies seeking recyclable and lower-carbon packaging solutions.

1. Environmentally Responsible Material

Eco-friendly HIPS rolls are made using recyclable raw materials, reducing plastic waste and supporting circular economy initiatives. Many manufacturers also adopt energy-efficient and low-emission production methods.

2. Excellent Thermoforming Performance

HIPS is widely used for thermoforming because it:

This makes it ideal for high-speed automated production lines.

3. High Impact Resistance with Lightweight Structure

Although lightweight, HIPS provides strong toughness and impact resistance, protecting packaged items such as electronics, tools, or consumer goods.

4. Safe, Non-Toxic, and Odor-Free

Eco-Friendly HIPS Plastic Rolls are:

This ensures safety in sensitive industries.

5. Superior Printability for Branding

The smooth surface of HIPS plastic rolls makes them ideal for high-quality printing and graphic design, allowing manufacturers to create eye-catching packaging and displays.

| Industry / Buyer Type | Why They Need Eco-Friendly HIPS Plastic Rolls | Key Pain Points Solved |

|---|---|---|

| 1. Food Packaging Manufacturers | For producing food trays, fruit boxes, dairy and bakery packaging with recyclable, lightweight materials. | - Need safe, hygienic, non-toxic materials- Pressure to use eco-friendly packaging- Require stable thermoforming performance- Need to reduce production cost and waste |

| 2. Electronics Packaging Companies | For anti-static trays, blister packs, and protective packaging for electronic components. | - Sensitive components require anti-static protection- Need consistent thickness and stability- High risk of damage during transport- Need recyclable materials to meet regulations |

| 3. Cosmetic & Personal Care Brands | To create attractive blister packs, display trays, and packaging with high printability. | - Need high-end packaging appearance- Require smooth surfaces for printing- Want lightweight yet rigid packaging- Need customizable colors and finishes |

| 4. Medical Device Packaging Manufacturers | For sterile blister packs, disposable instrument trays, and healthcare product packaging. | - Need safe, odorless, non-toxic material- Require strict hygiene and compliance- Need stable production for sensitive products- Require customizable thickness and precision |

| 5. Toy, Hobby, and Stationery Manufacturers | For producing safe, durable, lightweight parts and packaging. | - Need child-safe, odor-free materials- Require strong impact resistance- Want cost-effective forming materials- Need recyclable plastics for sustainability goals |

| 6. Display, Advertising & Printing Companies | For signboards, POP displays, printed panels, and advertising materials. | - Need excellent print surface- Require smoothness and color consistency- Need lightweight but rigid materials- Want cost-effective alternatives to ABS/PVC |

| 7. Thermoforming Factories & OEM Manufacturers | For mass production of trays, containers, and custom-formed products. | - Require consistent forming performance- Need materials that reduce machine downtime- Want fast forming with lower energy cost- Need customizable width, thickness, and color |

| 8. Brands Focused on Sustainability (Any Industry) | For replacing traditional plastics with recyclable, low-carbon materials. | - Pressure from consumers and regulations to go green- Need recyclable packaging solutions- Want to reduce carbon emissions- Need eco-friendly alternatives without raising cost |

Businesses select eco-friendly HIPS because it solves common production and environmental challenges:

This combination of sustainability + performance makes it a preferred material in modern packaging manufacturing.

Eco-Friendly HIPS Plastic Rolls are recyclable, safe, durable, and efficient materials designed for manufacturers who want high-performance plastic sheets without compromising environmental responsibility. With excellent forming properties, stable quality, and wide customization options, eco-friendly HIPS is becoming a leading choice for sustainable packaging and product manufacturing.

|

Product Name |

Eco-Friendly HIPS Plastic Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

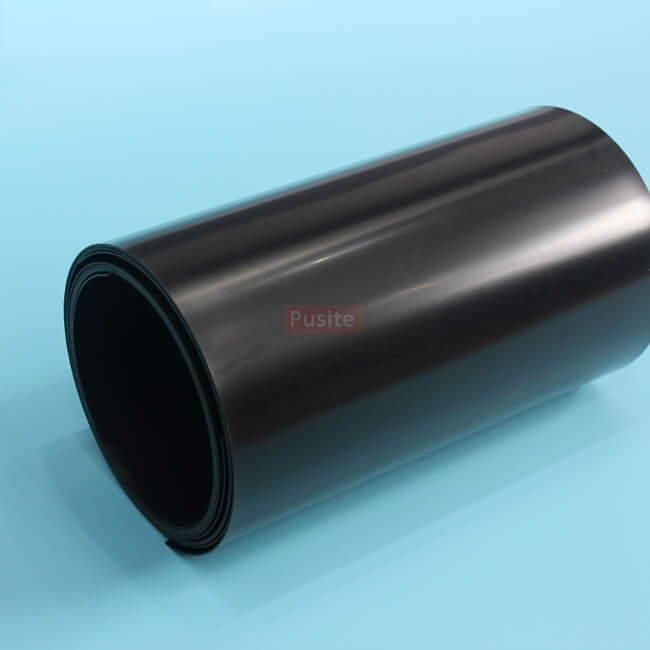

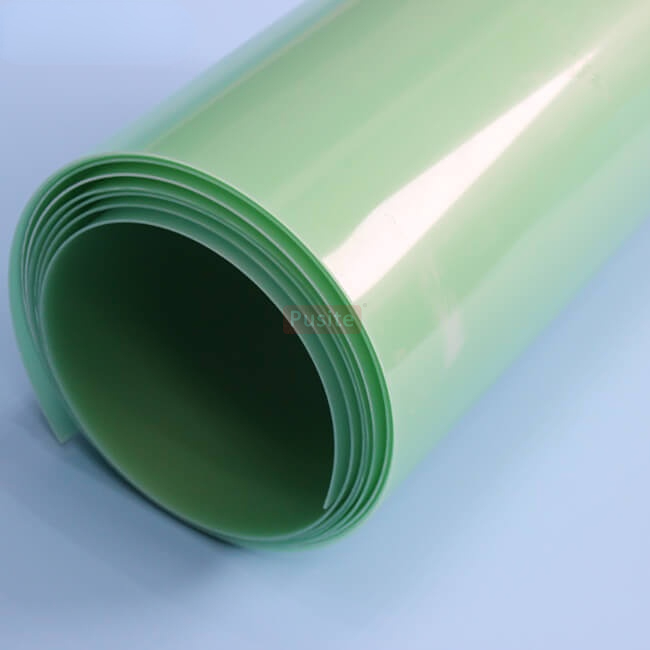

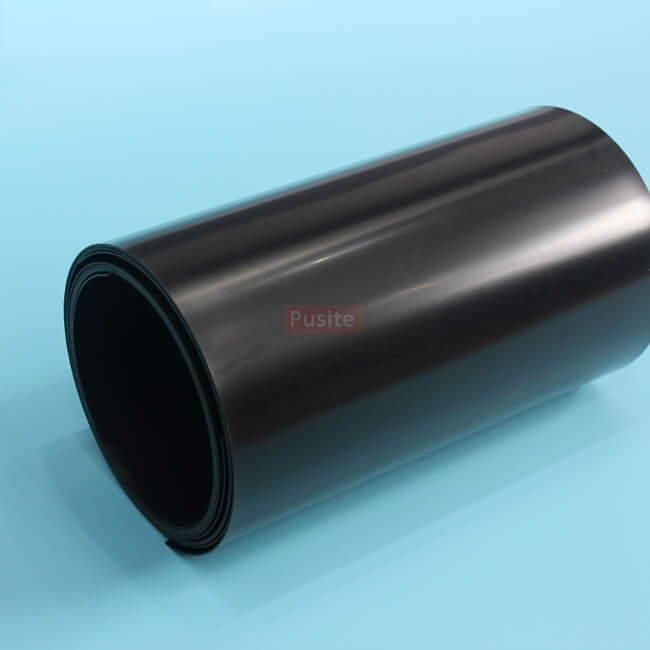

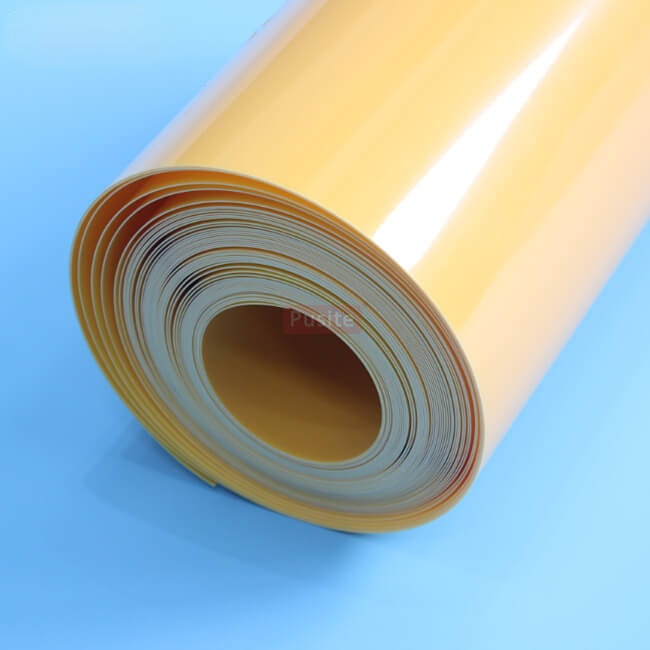

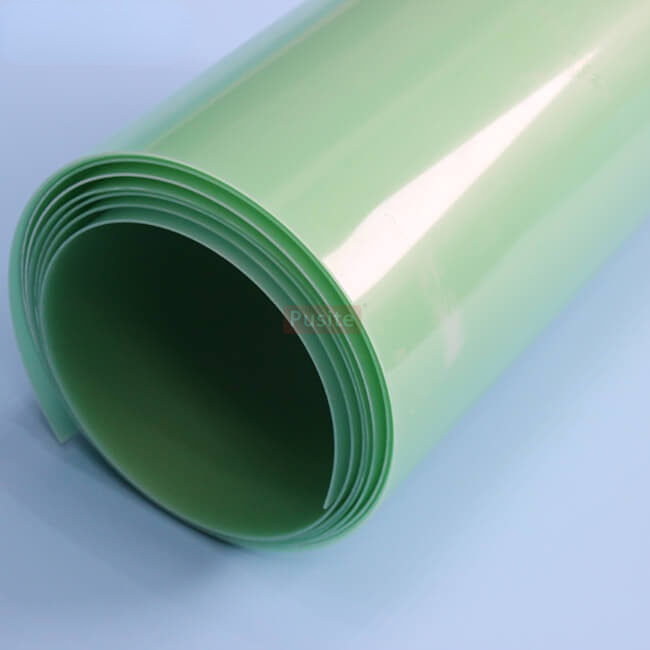

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.