Introduction

In modern electronics manufacturing and assembly, protecting sensitive components from electrostatic discharge (ESD) is critical.

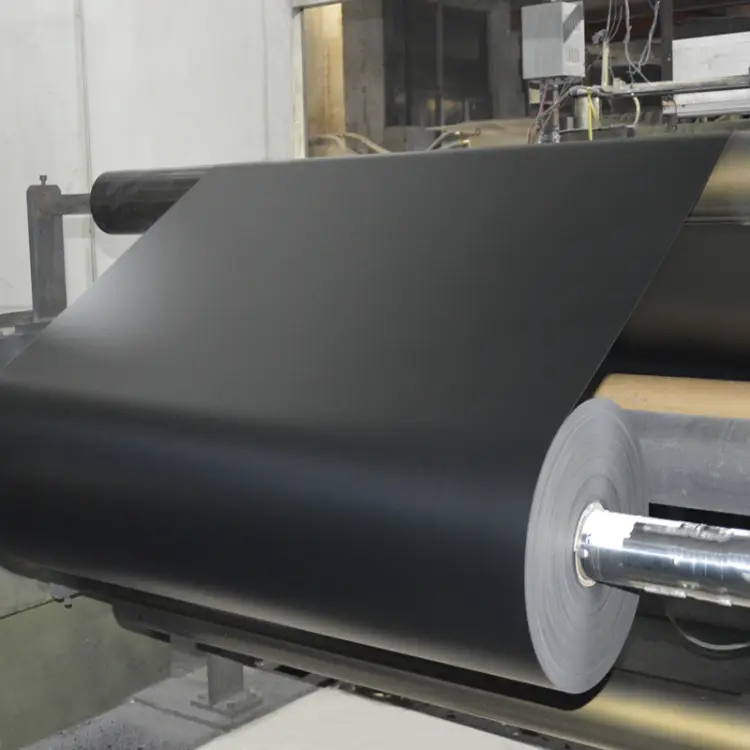

ESD HIPS (High Impact Polystyrene) plastic sheet rolls are specialized industrial materials designed for thermoformed packaging trays that safely store, transport, and handle electronic components.

These materials provide a reliable solution for B2B packaging needs where ESD control is essential.

Understanding ESD HIPS

High Impact Polystyrene (HIPS) is a versatile thermoplastic known for its excellent rigidity, dimensional stability, and ease of thermoforming. When combined with ESD (Electrostatic Discharge) properties, HIPS becomes suitable for applications where static electricity could damage sensitive electronic components. Electrostatic discharge is a critical concern in electronics manufacturing, as even minor static events can compromise semiconductor devices, integrated circuits, or other electronic parts.

ESD HIPS plastic sheet rolls are engineered to have controlled surface resistivity, allowing them to dissipate static charges safely. Unlike standard HIPS, which can accumulate and hold static, ESD HIPS ensures that static charges are neutralized, preventing potential damage during handling, assembly, and transportation.

Key Properties of ESD HIPS Plastic Rolls

Several characteristics make ESD HIPS an ideal material for tray-based packaging in electronics and high-precision manufacturing:

1. Electrostatic Dissipation: ESD HIPS is formulated to maintain surface resistivity within the antistatic range, typically between 10^5 and 10^11 ohms per square. This property reduces the risk of static-induced component failure.

2. Impact Resistance: The “high impact” nature of HIPS allows trays to absorb shocks and mechanical stress during transport or automated handling.

3. Thermoformability: ESD HIPS sheet rolls can be easily thermoformed into custom tray shapes, compartments, and cavities suitable for various components, from semiconductors to connectors.

4. Chemical Stability: ESD HIPS exhibits resistance to mild acids, bases, and common cleaning agents used in electronics production lines, ensuring durability and cleanliness.

5. Dimensional Accuracy: Uniform thickness and stable sheet properties ensure precise tray formation, which is crucial for automated pick-and-place systems used in modern electronics assembly.

Applications in Tray-Based Electronics Packaging

ESD HIPS plastic sheet rolls are widely used in the electronics sector for producing trays that hold, protect, and transport components safely. Typical applications include:

1. IC Trays: Integrated circuits, memory chips, and microcontrollers require trays that prevent static damage during storage and shipping.

2. Connector Trays: Sockets, plugs, and connectors benefit from custom thermoformed compartments that maintain orientation and spacing.

3. PCB Holders: Printed circuit boards (PCBs) can be transported on ESD trays without the risk of electrostatic discharge or mechanical bending.

4. Automated Production Lines: Many assembly lines rely on pick-and-place machines that require trays with precise dimensions and stable, non-static surfaces.

Advantages Over Alternative Materials

While other materials, such as polypropylene (PP) or standard polystyrene, are also used in packaging, ESD HIPS plastic rolls offers several advantages for B2B industrial applications:

1. Enhanced Static Protection: Unlike standard HIPS or PP, ESD HIPS actively mitigates electrostatic risks, a critical requirement in electronics.

2. Superior Forming Capability: HIPS exhibits better thermoforming behavior than many other plastics, allowing intricate tray designs.

3. Consistent Mechanical Performance: The impact resistance and rigidity of ESD HIPS reduce the risk of tray deformation under load.

| Feature / Property | ESD HIPS Plastic Rolls | HIPS Plastic Rolls | PP Plastic Rolls |

|---|---|---|---|

| Full Name | Electrostatic Discharge High Impact Polystyrene | High Impact Polystyrene | Polypropylene |

| Electrostatic Protection | Yes – dissipates static, prevents ESD damage | No – can accumulate static | No – generally non-ESD |

| Impact Resistance | High – reinforced HIPS | High | Medium – less impact resistant than HIPS |

| Rigidity / Stiffness | High | High | Medium – more flexible than HIPS |

| Thermoformability | Excellent – suitable for tray forming | Excellent – easy to thermoform | Good – can be thermoformed but less precise |

| Chemical Resistance | Moderate – resistant to mild acids & bases | Moderate | High – resistant to acids, bases, and solvents |

| Typical Applications | Electronics trays, antistatic packaging | Food trays, display trays, packaging inserts | Food containers, bottles, industrial packaging |

| Cost Level | Higher – specialized material | Medium | Lower |

| Temperature Resistance | ~70–80°C (HIPS base) | ~70–80°C | ~100–120°C |

| Recyclability | Yes – depends on local recycling standards | Yes | Yes |

| Surface Finish | Smooth, antistatic | Smooth | Smooth or slightly textured |

Considerations for Manufacturers and B2B Buyers

When selecting ESD HIPS plastic sheet rolls for tray production, industrial buyers should consider several factors:

1. Sheet Thickness: Depending on the weight and fragility of the components, sheet thickness can vary. Thicker sheets provide more impact resistance but may be less flexible for intricate designs.

2. Surface Resistivity Range: Ensure that the ESD HIPS grade meets the required electrostatic protection levels for your specific components.

3. Thermoforming Compatibility: Check that the material is compatible with your tray-forming equipment and processes.

4. Quality and Consistency: For high-volume production, consistent sheet thickness, flatness, and material properties are critical to maintain production efficiency and reduce waste.

ESD HIPS in Global Electronics Supply Chains

The global electronics industry increasingly relies on standardized packaging solutions that combine mechanical protection with electrostatic safety.

ESD HIPS trays have become a core component of this supply chain, supporting everything from component storage to automated assembly and distribution.

Manufacturers and contract packagers favor ESD HIPS sheets for their ability to maintain product integrity while streamlining operations.

Conclusion

ESD HIPS plastic sheet rolls are an essential material in industrial electronics packaging, particularly for tray-based systems.

Their combination of electrostatic protection, impact resistance, and thermoformability makes them a reliable choice for manufacturers, distributors, and assembly service providers who need to safeguard sensitive electronic components.

For B2B buyers in electronics and high-precision manufacturing, selecting the right ESD HIPS sheet is a critical step in ensuring both product quality and operational efficiency.

By focusing on industrial-grade performance, standardized electrostatic protection, and adaptable thermoforming capabilities, ESD HIPS continues to play a vital role in modern electronics packaging solutions.

Why Choose Pusite ESD HIPS Plastic Sheet Rolls?

As a leading manufacturer of high-quality plastic sheet rolls, Pusite is committed to delivering reliable and efficient solutions for industrial packaging and electronics applications.

Our ESD HIPS (Electrostatic Discharge High Impact Polystyrene) plastic sheet rolls are specifically designed to meet the demands of modern tray-based packaging and assembly lines.

Here are the key reasons why industrial buyers and packaging professionals choose Pusite:

1. Industry-Grade ESD Protection

Pusite ESD HIPS sheet rolls are engineered to safely dissipate static charges, protecting sensitive electronic components during storage, transport, and assembly.

Our materials maintain controlled surface resistivity, minimizing the risk of electrostatic discharge (ESD) that could compromise delicate electronic devices.

2. Superior Material Quality and Consistency

We maintain strict quality control throughout our production process to ensure uniform sheet thickness, flatness, and mechanical performance.

This consistency is essential for automated tray forming, pick-and-place operations, and high-volume production environments.

3. Excellent Thermoforming Performance

Pusite ESD HIPS sheets offer excellent thermoformability, allowing manufacturers to create customized tray designs with precise compartments.

Our sheets are compatible with a wide range of industrial thermoforming equipment, ensuring smooth production with minimal material waste.

4. High Impact Resistance and Durability

The high-impact properties of our HIPS sheets provide mechanical strength and resilience, protecting components from shocks, vibrations, and handling stresses.

This makes Pusite sheets ideal for both assembly lines and logistics-intensive supply chains.

5. Chemical and Temperature Stability

Our ESD HIPS sheets are resistant to common cleaning agents, mild acids, and bases used in electronics production.

They maintain dimensional stability under typical operating temperatures, ensuring reliable performance in diverse industrial conditions.

6. Direct Manufacturer Advantage

As a manufacturer, Pusite offers direct access to raw sheet materials, enabling stable supply, competitive pricing, and tailored solutions for bulk orders.

Our team works closely with industrial customers to meet specific requirements, from sheet thickness and ESD grades to customized roll sizes.

7. B2B-Focused Support

We focus exclusively on industrial and manufacturing clients, providing technical support and consultation for packaging projects.

Our engineers assist in selecting the appropriate sheet grades, optimizing tray designs, and ensuring seamless integration into production workflows.

Contact US

If you would like to learn more about ESD HIPS plastic sheet rolls, please contact us.