Introduction

In today’s competitive and highly regulated food packaging industry, manufacturers are under increasing pressure to deliver packaging that is safe, consistent, cost-efficient, and suitable for high-speed production.

Selecting the right plastic raw material — and more importantly, the right supplier — has become a critical decision for long-term success.

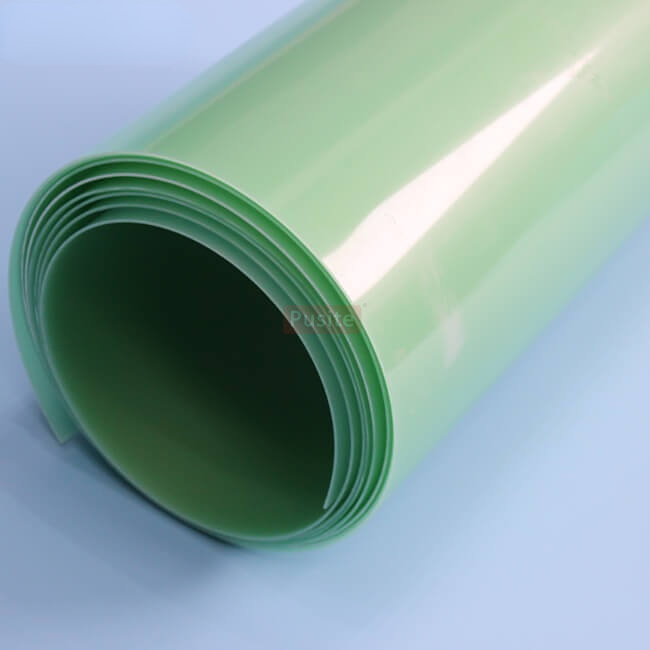

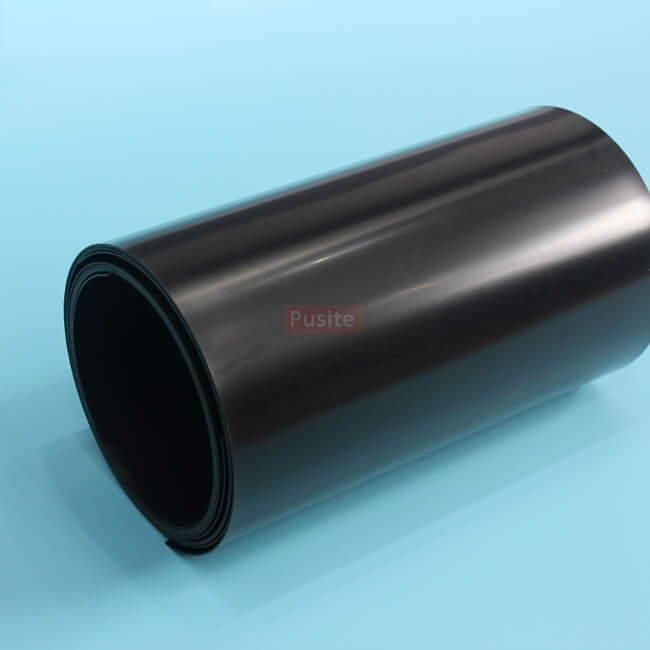

Food Grade HIPS Plastic Roll has emerged as a preferred solution for many food packaging and thermoforming manufacturers worldwide.

As a professional manufacturer, Pusite provides reliable, production-ready Food Grade HIPS Plastic Rolls designed specifically for industrial food packaging applications.

Understanding Food Grade HIPS Plastic Roll

High Impact Polystyrene (HIPS) is widely used in food packaging due to its excellent rigidity, impact resistance, and processability. When manufactured with food-grade compliant raw materials and controlled extrusion processes, HIPS plastic rolls are suitable for direct food contact and mass production.

Typical applications include:

- Dairy and yogurt containers

- Bakery trays and dessert cups

- Disposable food trays and lids

- Thermoformed food packaging components

However, not all HIPS sheets or rolls are suitable for food contact. Material purity, process control, and manufacturing discipline are essential. This is where Pusite’s manufacturing expertise makes a clear difference.

Certified Food-Grade Raw Materials from the Source

Food safety begins with raw material selection.

Pusite uses 100% food-grade compliant virgin materials for its Food Grade HIPS Plastic Rolls. All raw materials are carefully selected to meet food contact requirements and are processed in a controlled production environment.

Key raw material advantages include:

- No recycled content for food-contact applications

- No harmful additives or contaminants

- Consistent resin quality for stable extrusion

By controlling the raw material stage, Pusite ensures that every Food Grade HIPS Plastic Roll meets the safety expectations of professional food packaging manufacturers.

Stable Thickness Control for Industrial Production

For thermoforming and food packaging factories, thickness consistency directly impacts:

- Forming quality

- Scrap rate

- Production efficiency

Pusite operates advanced extrusion lines with strict thickness tolerance control. Each roll is monitored throughout the production process to ensure:

- Uniform thickness across the full roll width

- Excellent flatness and winding quality

- Reliable performance on automated thermoforming lines

This level of consistency allows customers to maintain stable production parameters, reduce material waste, and achieve predictable forming results.

Optimized Thermoforming Performance

Food packaging manufacturers demand materials that perform reliably under real production conditions.

Pusite Food Grade HIPS Plastic Rolls are engineered to offer:

- Smooth heating behavior

- Excellent forming definition

- Clean cutting and edge performance

- Good rigidity after forming

These characteristics make Pusite HIPS rolls ideal for high-speed thermoforming processes where efficiency, repeatability, and finished product appearance are critical.

Clean Manufacturing Environment & Quality Control

As a professional manufacturer, Pusite places strong emphasis on process control and quality assurance.

Our production system includes:

- Controlled extrusion conditions

- In-line quality inspections

- Batch traceability management

Each Food Grade HIPS Plastic Roll is produced following standardized procedures designed to minimize variation and ensure consistent quality from batch to batch.

This manufacturing discipline provides customers with confidence when scaling production or supplying demanding food packaging markets.

Designed for Food Packaging, Not Consumer Use

Unlike general-purpose plastic sheets, Pusite Food Grade HIPS Plastic Rolls are designed specifically for B2B industrial applications.

Our materials are developed for:

- Food packaging manufacturers

- Thermoforming factories

- OEM / ODM packaging converters

- Brand owners with stable supply requirements

Pusite does not position its Food Grade HIPS products for retail or consumer use, allowing full focus on industrial performance, compliance, and supply stability.

Customization to Match Your Production Line

Different food packaging lines require different material specifications.

Pusite offers customized Food Grade HIPS Plastic Roll solutions, including:

- Thickness options

- Roll width and diameter customization

- Surface finish adjustments

By working closely with customers, we help optimize material parameters to match specific thermoforming equipment and product designs.

This customization capability is especially valuable for customers seeking consistent long-term production results.

Reliable Supply Capacity for Long-Term Cooperation

A stable supply chain is essential for food packaging operations.

Pusite operates with:

- Independent manufacturing facilities

- Stable production capacity

- Structured production scheduling

This enables us to support customers with reliable lead times and consistent supply, even for repeat or large-volume orders.

Long-term cooperation is a key focus of Pusite’s business philosophy.

Professional Export & International Market Experience

Pusite has extensive experience serving international B2B customers.

Our export capabilities include:

- Clear documentation for international shipments

- Professional logistics coordination

- Experience supporting different regulatory environments

This makes Pusite a dependable partner for food packaging manufacturers supplying both domestic and export markets.

Why Food Packaging Manufacturers Trust Pusite?

Customers choose Pusite not only for the material itself, but for the overall manufacturing reliability behind it.

Key reasons include:

- Consistent food-grade compliance

- Stable product quality

- Professional manufacturing management

- Long-term supply reliability

Pusite understands the operational challenges faced by food packaging manufacturers and focuses on providing materials that work consistently in real production environments.

Partner with Pusite for Food Grade HIPS Plastic Rolls

Choosing the right Food Grade HIPS Plastic Roll supplier is a strategic decision that impacts product safety, production efficiency, and brand reputation.

As a dedicated Food Grade HIPS Plastic Roll manufacturer, Pusite is committed to supporting food packaging manufacturers with reliable materials, stable quality, and professional service.

If you are looking for a long-term partner for Food Grade HIPS Plastic Rolls for food packaging and thermoforming, Pusite is ready to support your business.