Professional Procurement Guide for Food Packaging Projects

Food Grade HIPS (High Impact Polystyrene) Plastic Rolls are widely used in industrial food packaging applications, including thermoformed trays, cups, lids, dairy containers, and disposable food boxes.

For food packaging manufacturers, OEM factories, and industrial buyers, selecting the right HIPS material is not a consumer-level decision. It is a procurement and risk-control process that directly affects food safety compliance, production efficiency, and long-term project stability.

This guide outlines the key technical and commercial factors buyers should evaluate when sourcing Food Grade HIPS Plastic Rolls for mass production.

What Are Food Grade HIPS Plastic Rolls?

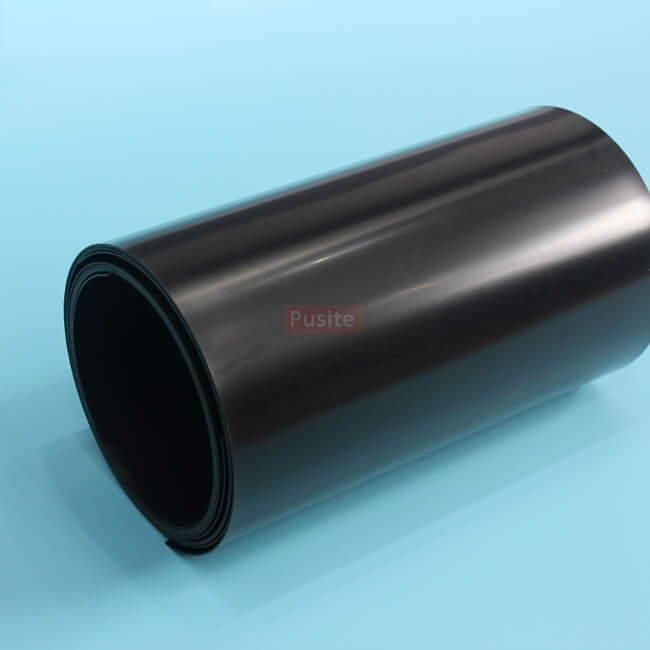

Food Grade HIPS (High Impact Polystyrene) Plastic Rolls are extruded polystyrene sheets supplied in roll form, specifically formulated for food-contact packaging.

They are commonly used as HIPS sheets for food packaging in:

- Thermoformed food trays

- Dairy cups and lids

- Takeaway and disposable food containers

- OEM food packaging lines

HIPS material offers good impact resistance, stable forming behavior, and cost efficiency for large-scale production.

Purchasing Considerations

1. Food Contact Compliance and Certifications

The first requirement for any food packaging material is regulatory compliance.

Industrial buyers should confirm that Food Grade HIPS Plastic Rolls comply with applicable food contact standards, including:

- FDA 21 CFR (USA)

- EU Regulation No. 10/2011

- GB 4806 food contact standards

What to check during procurement:

- Declaration of conformity for food contact

- Third-party laboratory test reports

- Raw material traceability

- Batch-level documentation

Without verifiable compliance, HIPS materials should not be approved for food packaging production.

2. Virgin Raw Material Requirements for Food Grade HIPS

For food-contact applications, 100% virgin HIPS resin is strongly recommended.

Using recycled or mixed materials may result in:

- Odor contamination

- Unstable forming behavior

- Potential food safety risks

Key verification points:

- Virgin-grade raw material only

- No recycled content in food-contact layers

- No restricted additives or heavy metals

Virgin HIPS provides consistent mechanical strength and stable hygiene performance in mass production.

3. Thickness Tolerance and Batch Consistency

Thickness control is critical when using HIPS thermoforming material on high-speed production lines.

Typical thickness range:

- 0.3 mm – 2.0 mm

Industrial buyer considerations:

- Tight thickness tolerance (e.g. ±0.03 mm)

- Uniform sheet flatness

- Stable roll winding

- Consistent performance across batches

Poor thickness consistency leads to higher scrap rates, unstable forming, and increased production costs.

4. Thermoforming Performance in Mass Production

Food Grade HIPS Plastic Rolls must perform reliably in continuous industrial thermoforming.

Applicable processes include:

- Vacuum forming

- Pressure forming

- Automatic cutting and stacking

Performance indicators:

- Stable heating window

- Low shrinkage during forming

- Clean cutting edges

- Good impact resistance after forming

High-quality HIPS material reduces machine adjustments, downtime, and energy consumption.

5. Choosing a Reliable Food Grade HIPS Plastic Rolls Supplier

Material quality alone is not enough. Supplier capability plays a key role in long-term projects.

A professional Food Grade HIPS Plastic Rolls supplier should offer:

- In-house extrusion production

- Documented quality control system

- Stable long-term supply capacity

- Custom width, thickness, color, and roll diameter

- Technical support for thermoforming applications

For OEM and large-scale food packaging projects, supply stability and batch consistency are critical success factors.

6. Procurement Checklist for Industrial Buyers

Before finalizing a supplier, food packaging manufacturers should confirm:

| No. | Evaluation Item | Key Requirements | Buyer Confirmation |

|---|---|---|---|

| 1 | Food Contact Compliance | Complies with FDA, EU food contact regulations and relevant standards | ✓ |

| 2 | Raw Material Quality | Manufactured using 100% virgin HIPS raw material, no recycled content | ✓ |

| 3 | Thickness Tolerance | Tight thickness control with minimal tolerance variation across the roll | ✓ |

| 4 | Batch Consistency | Stable color, surface finish, and mechanical properties between batches | ✓ |

| 5 | Thermoforming Performance | Proven performance in thermoforming without cracking or deformation | ✓ |

| 6 | Surface Quality | Smooth and clean surface suitable for direct food contact and printing | ✓ |

| 7 | Supplier Reliability | Manufacturer with long-term production capacity and stable supply chain | ✓ |

| 8 | Quality Control System | In-house quality control with documented inspection procedures | ✓ |

| 9 | Customization Capability | Support for customized thickness, width, and roll specifications | ✓ |

| 10 | Traceability & Documentation | Clear batch traceability with complete technical documentation | ✓ |

Tip for Buyers: Request technical datasheets, compliance certificates, and trial samples before bulk purchasing to ensure suitability for your food packaging application.

Why Choose Pusite Food Grade HIPS Plastic Sheet Rolls?

When sourcing Food Grade HIPS Plastic Sheet Rolls for industrial food packaging projects, material compliance and supplier reliability are just as important as price.

Pusite is a professional manufacturer focused on supplying production-ready HIPS sheets for food packaging manufacturers, OEM factories, and large-scale packaging projects.

Our Food Grade HIPS materials are designed to support stable thermoforming performance, strict food contact compliance, and long-term batch consistency.

We manufacture our HIPS plastic sheet rolls using 100% virgin raw materials under controlled extrusion processes, ensuring consistent thickness, clean surface quality, and reliable forming behavior in mass production.

Each batch can be supported with relevant food contact documentation and traceable quality records, helping customers reduce regulatory and audit risks.

With in-house production capacity, strict quality control systems, and flexible customization capabilities, Pusite is able to support long-term supply programs for industrial food packaging lines.

Our team works closely with customers to ensure that our HIPS sheets integrate smoothly into existing thermoforming equipment and production workflows.

By choosing Pusite Food Grade HIPS Plastic Sheet Rolls, you are working with a manufacturer committed to compliance, consistency, and supply stability—not short-term trading.

Pusite Food Grade HIPS Plastic Sheet Rolls are intended for industrial food packaging applications only, not for retail or personal use.