This guide compares PP and PET from a practical sourcing and application perspective.

For electronics packaging that demands absolute reliability, a high-quality PET transparent sheet with permanent, double-sided anti-static properties is non-negotiable.

Food Grade HIPS Plastic Roll has emerged as a preferred solution for many food packaging and thermoforming manufacturers worldwide.

With continuous thermoforming process upgrades, Food Grade HIPS plastic rolls are redefining what efficient food packaging looks like—lighter, stronger, and more reliable.

HIPS plastic rolls can be used for disposable food trays, yogurt cups, lids, and takeout containers.

Pusite food grade HIPS sheet rolls are manufactured under strict quality control, ensuring they are suitable for direct or indirect food contact and widely used in thermoformed food packaging products.

Food Grade HIPS plastic rolls have emerged as a preferred solution for food packaging due to their safety, durability, and excellent thermoforming performance.

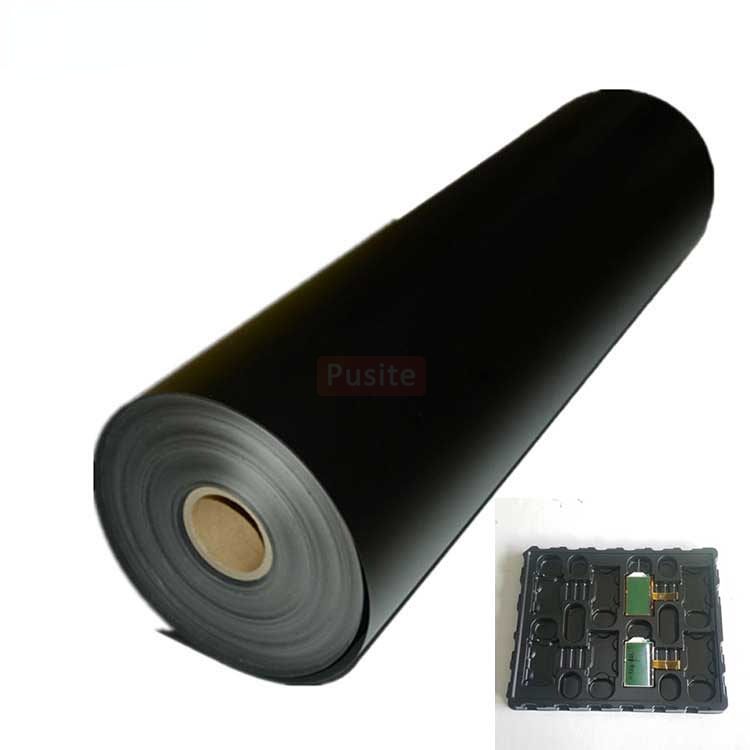

Introduction In modern electronics manufacturing and assembly, protecting sensitive components from electrostatic discharge (ESD) is critical. ESD HIPS (High Impact Polystyrene) plastic sheet rolls are specialized industrial materials designed for thermoformed packaging trays that safely store, transport, and handle electronic components. These materials provide a reliable solution for B2B packaging needs where ESD control is […]

HIPS (High Impact Polystyrene) Plastic Sheet Rolls have become a preferred choice for thermoforming factories, food packaging suppliers, and blister packaging manufacturers.

HIPS (High Impact Polystyrene) plastic sheet rolls are a cost-effective, impact-resistant thermoplastic material widely used in vacuum forming, thermoforming and packaging.