HIPS Plastic Rolls Advantages HIPS (High Impact Polystyrene) plastic rolls are a top choice for various industries due to their exceptional performance and wide range of applications. Here are the key advantages of HIPS plastic rolls and their usage across different sectors: 1. Exceptional Impact Strength One of the standout features of HIPS plastic rolls […]

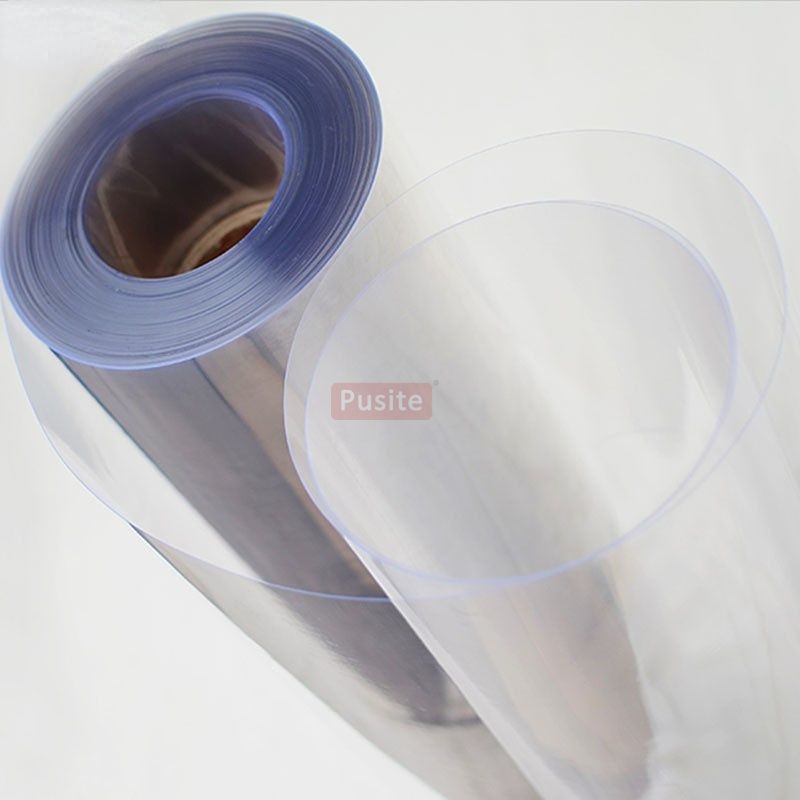

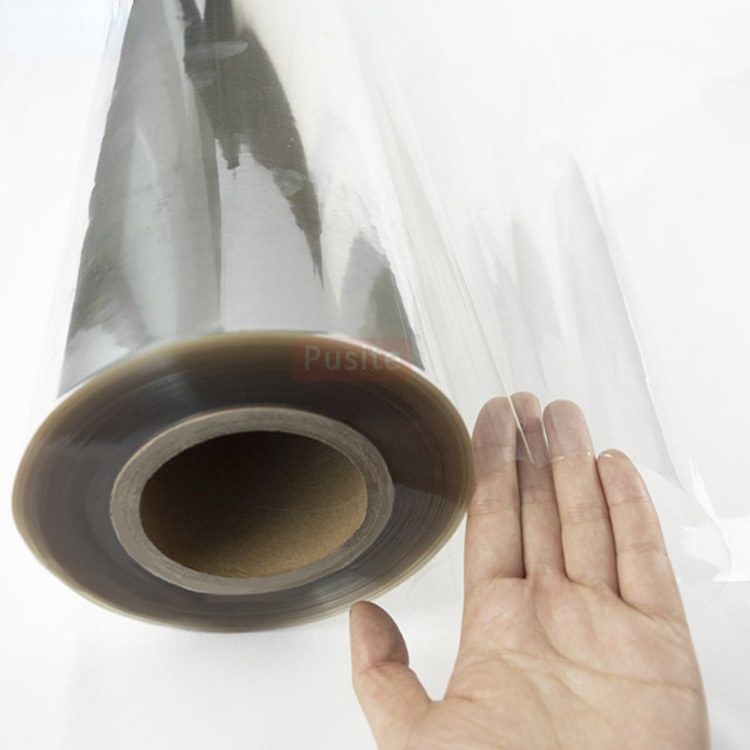

PET plastic sheet rolls advantages and application are recyclable material, it commonly used in food packaging and is FDA approved for direct food contact.

PET plastic sheet rolls are generally considered safe for food packaging. They are made from polyethylene terephthalate, which is a food-safe material.

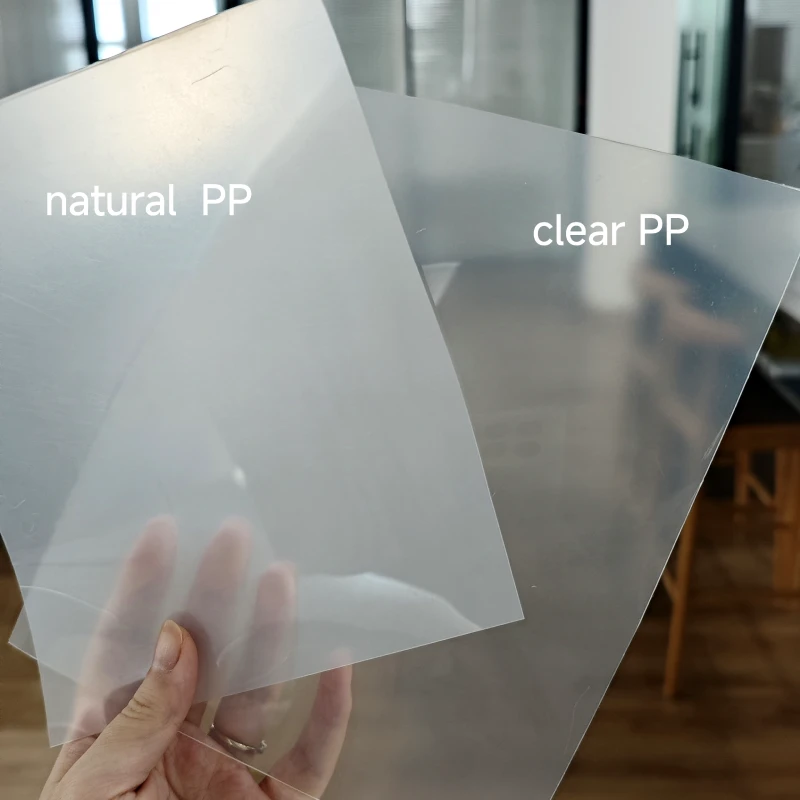

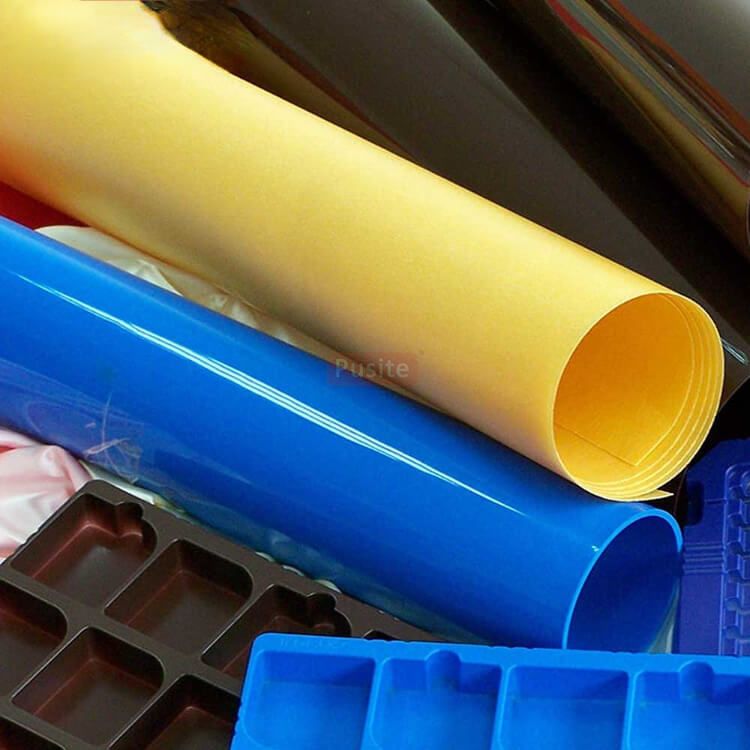

The differences between clear and natural polypropylene (PP) plastic sheets primarily revolve around their appearance, properties, and applications.

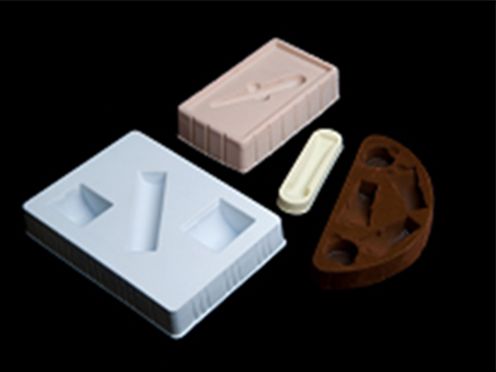

Application of PET plastic sheets PET plastic sheets have the following uses: 1. Blister Packaging: PET plastic sheets are used to create transparent blister packs for items like electronics, medical devices, and food products. They offer a secure yet visible packaging solution. 2. Food Trays and Containers: PET plastic sheets are widely used to produce […]

PP Plastic Sheet Rolls are suitable for frozen food packaging.

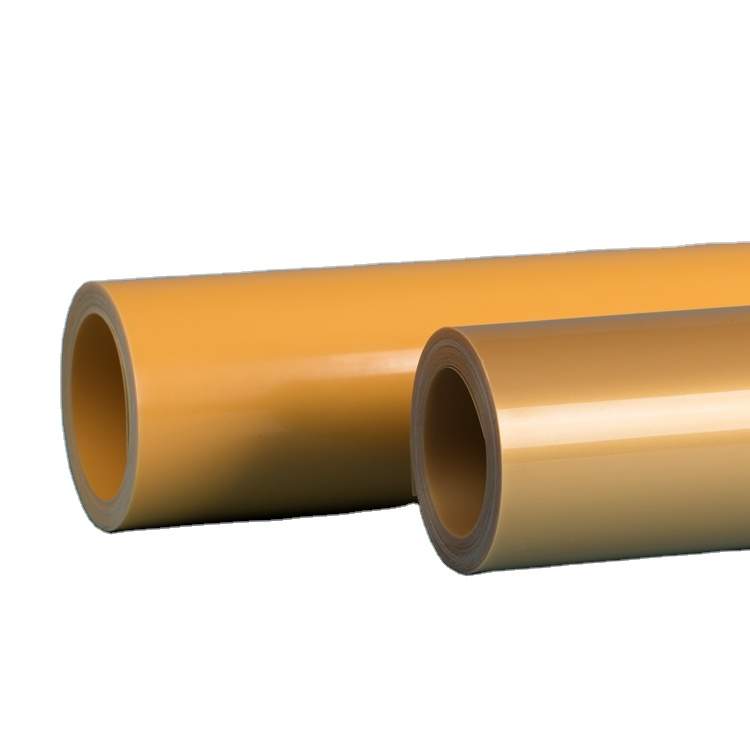

Colored PET (Polyethylene Terephthalate) plastic sheet rolls are produced through a series of well-defined processes that include polymer synthesis, extrusion, coloring, and finishing.

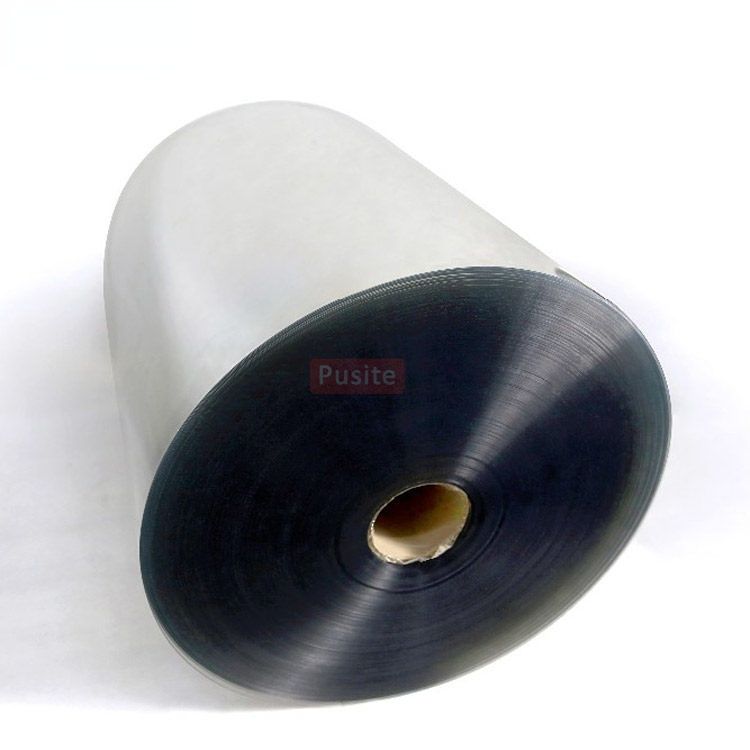

High impact polystyrene (HIPS) plastic roll antistatic is widely used in electronic product packaging, HIPS plastic roll itself is a non-conductive material. The antistatic effect of HIPS plastic roll can be increased by adding antistatic agent, modifying HIPS resin, etc.

HIPS plastic ( high impact polystyrene plastic) rolls is a commonly used cosmetic plastic packaging material.

20 tons Pet plastic rolls shipped to Indonesia