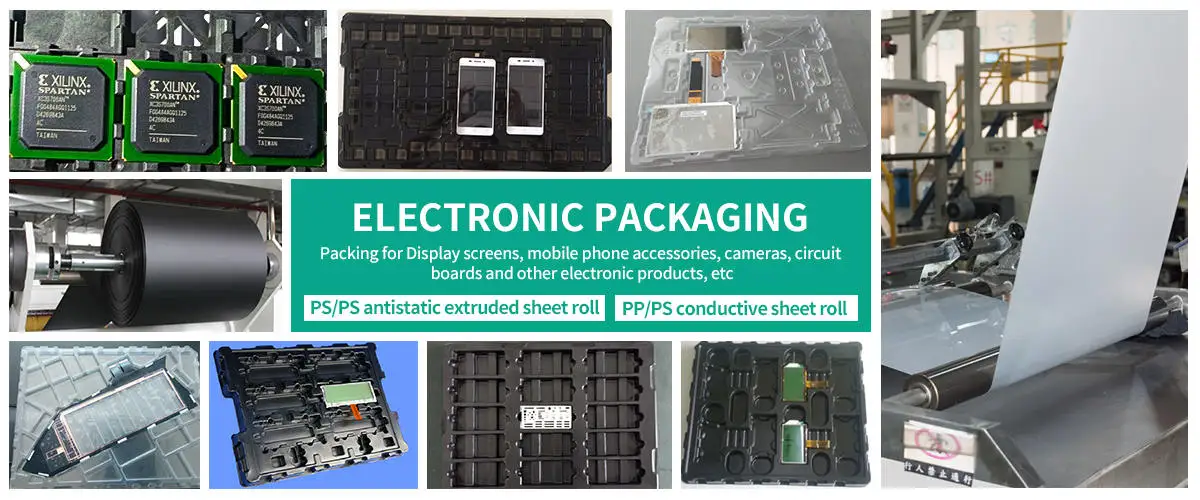

Why choose HIPS plastic rolls for electronic tray?

The main reasons for choosing HIPS plastic rolls to make electronic pallets are as follows:

1. Strong impact resistance: HIPS plastic rolls has good impact resistance and can withstand collisions and extrusions during transportation and use, protecting electronic products from damage.

2. Electrical insulation performance: HIPS plastic rolls are an excellent electrical insulation material, which can effectively block current, reduce the generation of static electricity, and protect the safety performance of electronic products.

3. Good molding and processing performance: HIPS plastic rolls are easy to process and form, and can be processed into the required shape and size through roll materials, adapting to the size and shape requirements of various electronic products.

4. Lower cost: Compared with some other plastics, HIPS plastic rolls has relatively low raw material costs and relatively low production costs, making it suitable for mass production.

5. Environmental performance: HIPS plastic rolls are recyclable and meets environmental protection requirements. Choosing to use HIPS plastic to make electronic trays is in line with the development trend of environmental awareness.

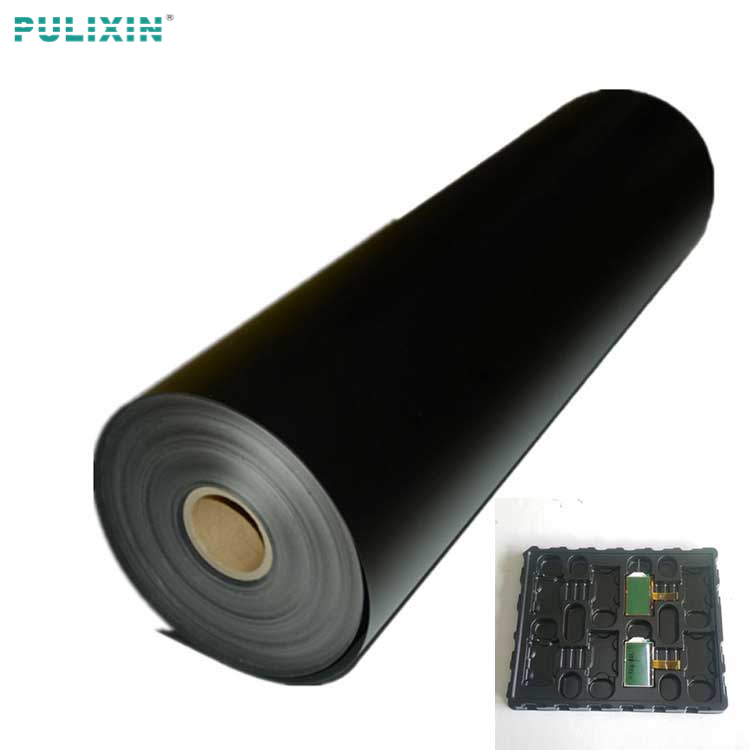

What is HIPS plastic rolls?

HIPS (high impact polystyrene) plastic roll is a continuous roll made of high impact polystyrene. HIPS plastic roll is a common plastic material that is commonly used to make packaging for a variety of products. |

|

HIPS plastic rolls polystyrene product connects polystyrene and rubber particles by adding micron-sized rubber particles and grafting them together. When subjected to an impact, the tip stress of the crack propagation will be released by the relatively soft rubber particles. Therefore, the crack propagation is hindered, and the impact resistance is improved. In addition to its excellent impact performance, it also has most of the advantages of PS, such as good rigidity, easy processing, high product gloss (gloss 85%) and easy coloring, but its tensile strength and transparency are reduced.

Specification of HIPS plastic rolls

Pusite (Shanghai) International Trade Co.,Ltd. can produce HIPS conductive plastic rolls, semi-conductive plastic rolls, anti-static plastic rolls, color sheet, printed plastic rolls, permanent anti-static plastic rolls, high gloss plastic rolls, high toughness plastic rolls, antibacterial plastic rolls, high barrier plastic rolls, transparent plastic rolls, flame retardant plastic rolls, UV protection plastic rolls, laminated plastic rolls, etc.| Item | High Impact Polystyrene Sheet Roll, HIPS Plastic Roll, Rgid HIPS Film |

| Brand | Pusite |

| Origin | Shanghai, China |

| Width | 300~850mm |

| Thickness | 0.2~2.0mm |

| Weight | 50-150kg/roll |

| Shape | Roll/Sheet |

| Material | 100% virgin |

| Color | Black, White, Color, Natural, Transparent, Translucent. |

| Performance | Conductive, Antistatic, EOVH High barrier |

| Surface treatment | Matte, high gloss, flocking, etc. |

What is an electronic tray?

An electronic tray typically refers to a tray-like device equipped with electronic components, often used in various applications for automation, data collection, or control purposes. These trays can vary significantly in size, shape, and functionality based on their intended use.In some contexts, an electronic tray could refer to a component of a larger electronic system, such as a tray used in manufacturing processes for sorting or transporting electronic components. In other cases, it might refer to a standalone device, such as a tray with built-in sensors for monitoring or controlling environmental conditions like temperature or humidity.