Growing Concerns in Electronics Packaging

In recent years, the electronics industry has faced increasing challenges with product safety during storage and transportation. Traditional plastic packaging, while cost-effective, has proven inadequate in protecting sensitive electronic components from static electricity damage. This has driven the packaging sector to seek more advanced materials.

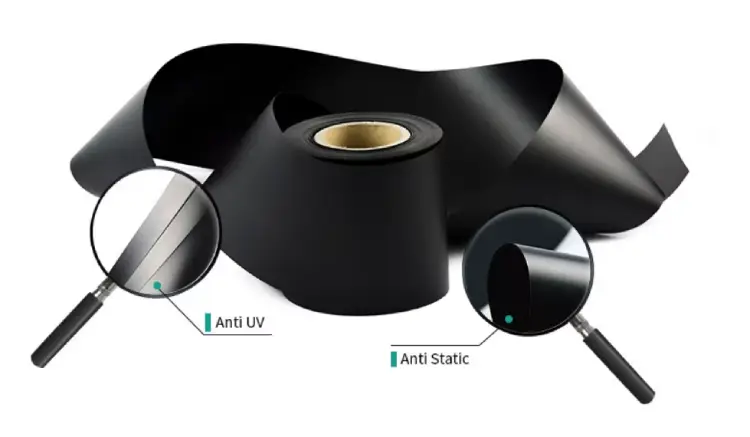

Advantages of Anti-Static HIPS Plastic Rolls

1.Superior Static Protection

Traditional plastics can generate static charges that may damage delicate electronic circuits or components. Anti-static HIPS plastic rolls are engineered to dissipate static electricity, ensuring that sensitive products remain safe during storage and transportation.

2. Enhanced Impact Resistance

Unlike many standard plastics, HIPS is known for its high impact resistance. This means the packaging can withstand external shocks or pressure, providing an extra layer of durability that traditional packaging often lacks.

3. Consistent Surface Performance

Standard plastics may attract dust or lint, compromising product quality and cleanliness. Anti-static HIPS rolls feature a uniform surface with anti-dust properties, making them an ideal choice for industries that demand cleanliness and precision, such as electronics, medical devices, and optical components.

4. Versatility in Thermoforming

Anti-static HIPS plastic rolls are highly versatile and suitable for various thermoforming processes. They can be shaped into trays, blisters, or custom packaging designs without losing their anti-static properties—something traditional plastics can’t always guarantee.

5. Cost-Effective Long-Term Solution

Although anti-static HIPS may initially cost more than standard plastics, its protective properties reduce the risk of damaged goods, returns, and product failures. This translates to long-term savings and greater customer satisfaction.

Market Outlook

With the continued growth of the global electronics market, the demand for advanced packaging materials like Anti-Static HIPS Plastic Rolls is expected to surge. Packaging manufacturers are investing in production capacity to meet this rising need, ensuring stable supply for industries worldwide.

Why Choose Pusite Anti-Static HIPS Plastic Rolls?

1. Factory-Direct Quality

Pusite manufactures Anti-Static HIPS plastic rolls with strict quality control, ensuring consistent performance and reliability.

2. Advanced Anti-Static Technology

Our materials are engineered to effectively dissipate static electricity, providing maximum protection for sensitive electronics.

3. Customization Options

Pusite offers thickness, color, and size customization to meet diverse packaging needs in electronics, medical, and precision industries.

4. Strong Supply Capacity

With modern production facilities and efficient logistics, we guarantee stable supply and timely delivery for global customers.

5. Competitive Pricing & Service

Pusite combines cost-effective solutions with professional technical support, helping clients reduce risks and improve packaging efficiency.

Contact US

Please consult us for more information and look forward to your inquiry.