Anti-Static HIPS Plastic Rolls for Vacuum Forming in the Electronics Industry

Our Anti-Static HIPS (High Impact Polystyrene) Plastic Rolls are specifically designed to meet the stringent requirements of the electronics industry. With a reliable surface resistivity range (typically 10⁹–10¹¹ ohms), these rolls help protect sensitive electronic components from static discharge during packaging, transport, and handling.

Key Features of Anti-Static HIPS Plastic Rolls

Anti-Static Protection: Prevents electrostatic damage to sensitive components such as ICs, PCBs, and semiconductors.

Excellent Thermoformability: Smooth forming performance under vacuum forming and pressure forming processes.

Dimensional Stability: Maintains shape and integrity even in high-precision molding.

High Impact Strength: Offers enhanced durability and resistance to cracking or breakage.

Customizable: Available in various thicknesses, widths, colors (typically black or pink anti-static), and roll diameters to match your production line.

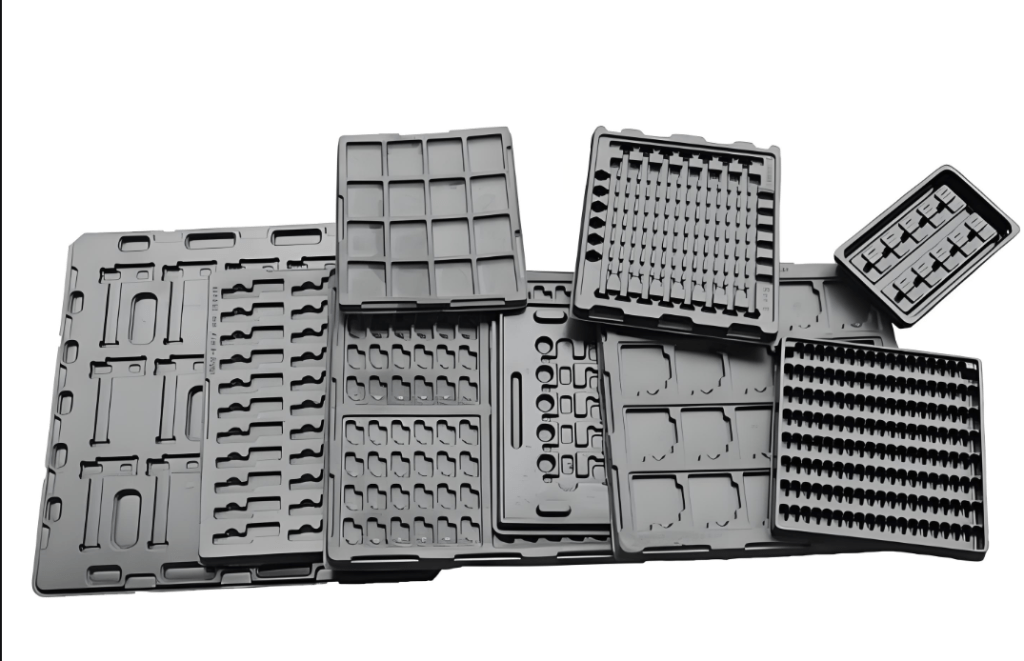

Application of Anti-Static HIPS Plastic Rolls

Anti-Static HIPS (High Impact Polystyrene) Plastic Rolls are commonly used for packaging products that are sensitive to static electricity or require protective, durable, and easily formable packaging. In English, you can describe their application like this:

1. Electronic components

- IC chips, circuit boards, capacitors, and other static-sensitive devices.

2. Consumer electronics

- Mobile phone accessories, headphones, batteries, and USB drives.

3. Medical devices

- Disposable syringes, diagnostic kits, and small medical instruments that require clean and static-free packaging.

4. Automotive parts

- Sensors, connectors, and small electronic modules.

5. Precision instruments and tools

- Instruments used in laboratories, testing equipment, and calibration devices.

6. Industrial components

- Electrical connectors, relays, and switches.

7. Blister and clamshell packaging

- Especially for retail products that need visibility and protection from static.

These rolls are especially ideal for vacuum forming trays, clamshells, blister packs, and component handling trays used in ESD-sensitive environments like cleanrooms, assembly lines, and logistics for electronics manufacturing.

Why Choose Us?

1. ESD Protection – Prevents static damage to electronic components

2. Easy to Form – Ideal for vacuum forming and thermoforming

3. Strong & Durable – High impact resistance for safe transport

4. Custom Sizes Available – Thickness, width, and color can be tailored

5. Stable Quality – Consistent performance and reliable supply

6. Factory Direct – Competitive price with professional service