One: The color is yellowish or grayish. Or there are yellow bars

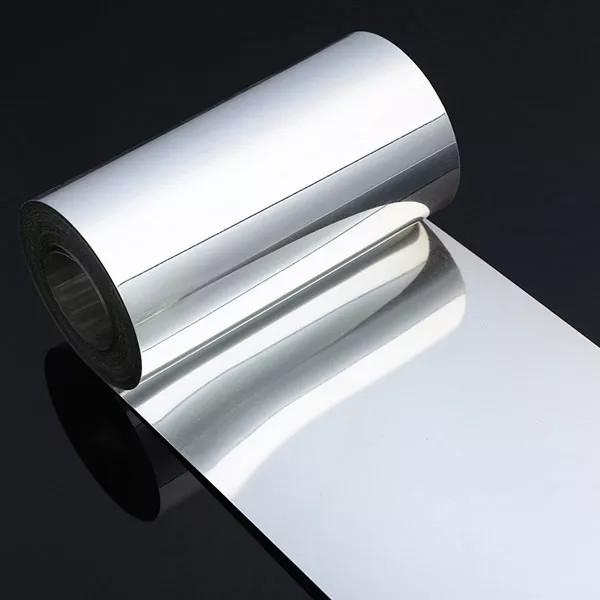

PET film, especially when it is rolled into a reel, the color is yellow or gray. It can be seen with the naked eye. If there are yellow bars, you must unfold the film or observe the light. Or spread it on a white backing for better identification.

Cause Analysis

Gel point, yellow point, black point" are the same. Yellowing is caused by poor thermal oxygen stability of the resin, or a large amount of air entering the extruder. When the resin is thermally oxidized, a large amount of acetaldehyde is produced. Due to acetaldehyde The antimony trioxide is reduced to antimony, causing the film (resin) to turn gray. The appearance of yellow bars usually occurs after replacing the filter or after replacing the resin. The reason is that there may be air entering during the replacement, or Part of the resin stays in the machine for too long, which makes some of the resin yellow, and after the formation of the yellow resin, it is impossible to mix well with the normal melting and plasticization, so yellow bars appear.

Two: too much static electricity

One characteristic of electrostatic phenomenon is adsorption. When the surface of the PET film is rubbed, or the film roll is peeled off, or the film is running at high speed, good electricity will be formed. If there is dust, paper scraps, hair, etc. near the membrane at this time, it may be adsorbed, which will affect the quality of the product membrane (especially the capacitor membrane). When the static electricity is serious, it may also cause fires, electricians and other accidents. Known polyester The static electricity of the film is too large, which will have a bad effect on the subsequent processing and processed products. For example, the static electricity size of the bonded PET film can be set at about 500v with an electrostatic tester, which indicates that the static electricity size on both sides of the film is also different.

Cause Analysis

PET film is a polar electrical insulating material, which makes it impossible to transfer the charges generated by friction, shearing, etc., and accumulates static electricity on its surface. The electrostatic size of the PET film and the electrical properties of the resin body. The application of additives. And it is related to the film making process. Because they directly affect the structure and properties of the film surface/surface, such as the crystallinity of the surface layer, the number of polar groups and their orientation, the size of the contact area between the two films, and other factors that affect the formation of static electricity. Based on this, it can also explain why the static electricity on both sides of the film is different.

Three: The bonding strength of printing, compounding and aluminizing is not enough

For the box bonding strength of India, composite, and vacuum aluminum plating, usually use tape as the inspection side. There are three types of conditions: full peeling, partial peeling, and non-peeling. The first two types are all of insufficient drilling strength.

Cause Analysis

The combined strength of PET film, ink and mink mixture is limited by the surface tension of PET film. The surface tension of the untreated PET film is 42~48N/S, which cannot meet the bonding strength requirement with the ink adhesive. Therefore, it is important to take some measures to increase the surface tension of 55N/cm or more such as corona treatment.