Material Composition:

HIPS PlasticPrice Range:

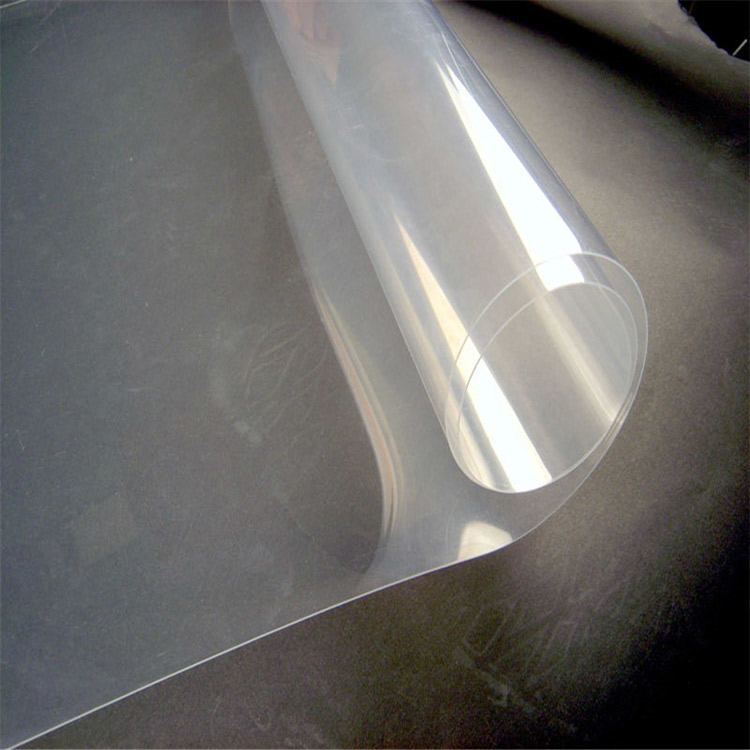

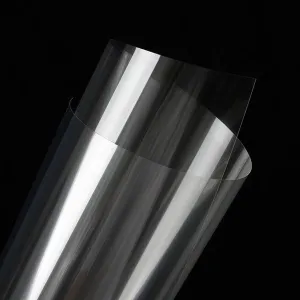

$1.28-$1.991mm conductive transparent PET plastic sheet rolls is a high performance, flexible plastic sheet designed for packaging applications requiring transparency and conductivity. Pusite is a professional PET plastic sheet rolls manufacturer. We can provide you with high-quality 1mm Conductive Transparent PET Plastic Sheet Rolls.

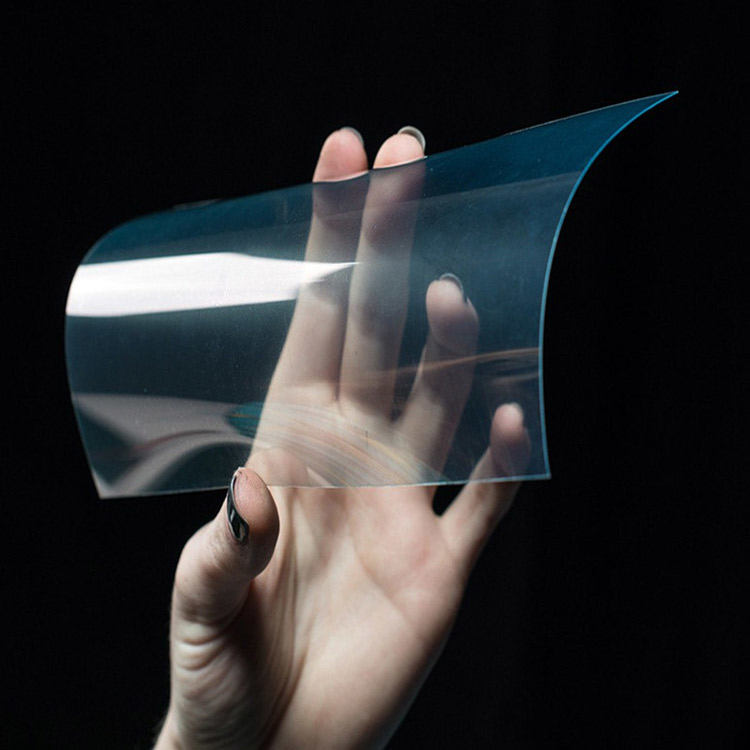

1mm Conductive Transparent PET Plastic Sheet Rolls are high-performance, flexible plastic sheets designed for applications requiring both transparency and electrical conductivity. These sheets are made from polyethylene terephthalate (PET) embedded with a conductive layer, making them ideal for touchscreens, EMI shielding, flexible electronics, and static control applications packing.

1. Conductive Surface

Surface resistivity: 10⁶ – 10⁸ ohms/sq, effectively prevents static buildup and protects sensitive electronic components.

2. High Transparency

Light transmittance above 85%, providing excellent visibility for display or inspection of packaged items.

3. Stable Thickness (1mm)

Uniform thickness ensures reliable thermoforming, die cutting, and consistent performance in automated production lines.

4.Thermoformable

Excellent moldability and form retention, ideal for ESD trays, blisters, and clamshell packaging.

5. Impact and Chemical Resistance

Offers superior mechanical strength and resistance to common chemicals, moisture, and abrasion.

6. Environmentally Friendly

Made from recyclable PET material, supporting eco-friendly and sustainable production goals.

7. Customizable Options

Available in different widths, lengths, surface textures (glossy/matte), and conductivity levels to meet specific needs.

8.Dimensional Stability

Excellent resistance to shrinkage and warping under heat and pressure, ensuring performance stability.

9. RoHS & REACH Compliant

Meets international safety and environmental standards for electronic and industrial packaging.

1mm Conductive Transparent PET Plastic Sheet Rolls can be used for packaging the following products:

| Property | Specification | Notes |

|---|---|---|

| Material | Conductive PET | Polyethylene Terephthalate with conductive coating |

| Thickness | 1.0 mm ±0.05mm | Standard thickness, customizable |

| Surface Resistivity | 10³-10⁶ Ω/sq | Adjustable based on requirements |

| Light Transmission | >85% | Visible light spectrum (400-700nm) |

| Haze | <2% | For optical clarity |

| Tensile Strength | ≥150 MPa | ASTM D882 standard |

| Operating Temperature | -30°C to +80°C | Short-term peak to 100°C |

| Thermal Expansion | 15-20 ppm/°C | Low expansion for dimensional stability |

| Roll Width | 300mm, 500mm, 1000mm (customizable) | Standard widths available |

| Roll Length | 10m, 20m, or custom lengths | Can be supplied as sheets |

| Moisture Absorption | <0.5% | 24h at 23°C/50% RH |

| Density | 1.38-1.40 g/cm³ | Lightweight material |

| Chemical Resistance | Resistant to most solvents, weak acids/alkalis | Avoid strong oxidizers |

1. Raw Material Preparation

High-quality polyethylene terephthalate (PET) resin is selected and blended with conductive agents (such as carbon nanotubes, conductive carbon black, or ITO coating materials) to impart conductivity while maintaining high transparency.

2. Extrusion Process

The blended raw materials are melted and extruded into sheets using a twin-screw or single-screw extruder. The extrusion temperature is controlled between 250–280°C to ensure uniform plasticization.

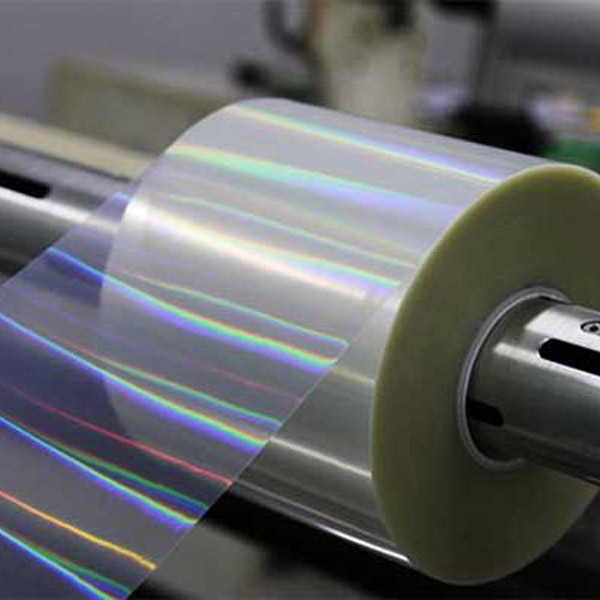

3. Calendering & Stretching

The molten PET is calendered into uniform 1mm thick sheets through a series of rollers. Biaxial orientation (BOPET process) may be applied to enhance mechanical strength and optical clarity.

4. Surface Treatment

Plasma treatment or inline coating can be applied to enhance surface conductivity and antistatic properties. High-end products may use ITO sputtering or coating to form a transparent conductive film.

5. Cooling & Rewinding

The sheet is rapidly cooled through chilled rollers to maintain flatness and smoothness. It is then cut and rewound into rolls as required, making it convenient for downstream applications such as printing and vacuum forming.

|

Product Name |

1mm Conductive Transparent PET Plastic Sheet Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

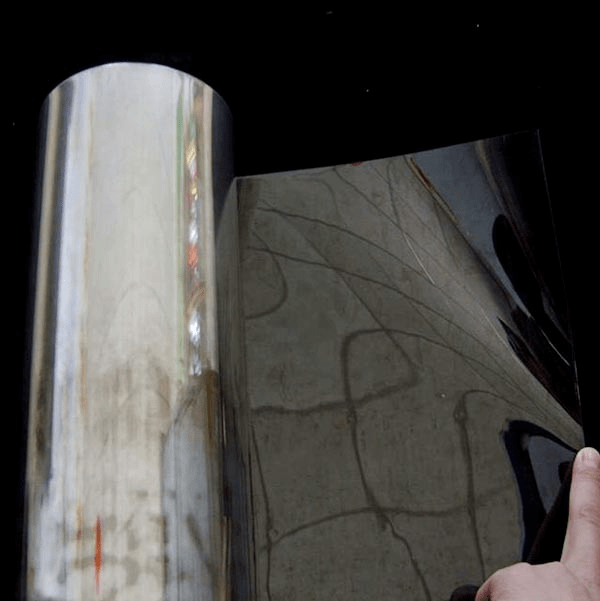

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.