Material Composition:

HIPS PlasticPrice Range:

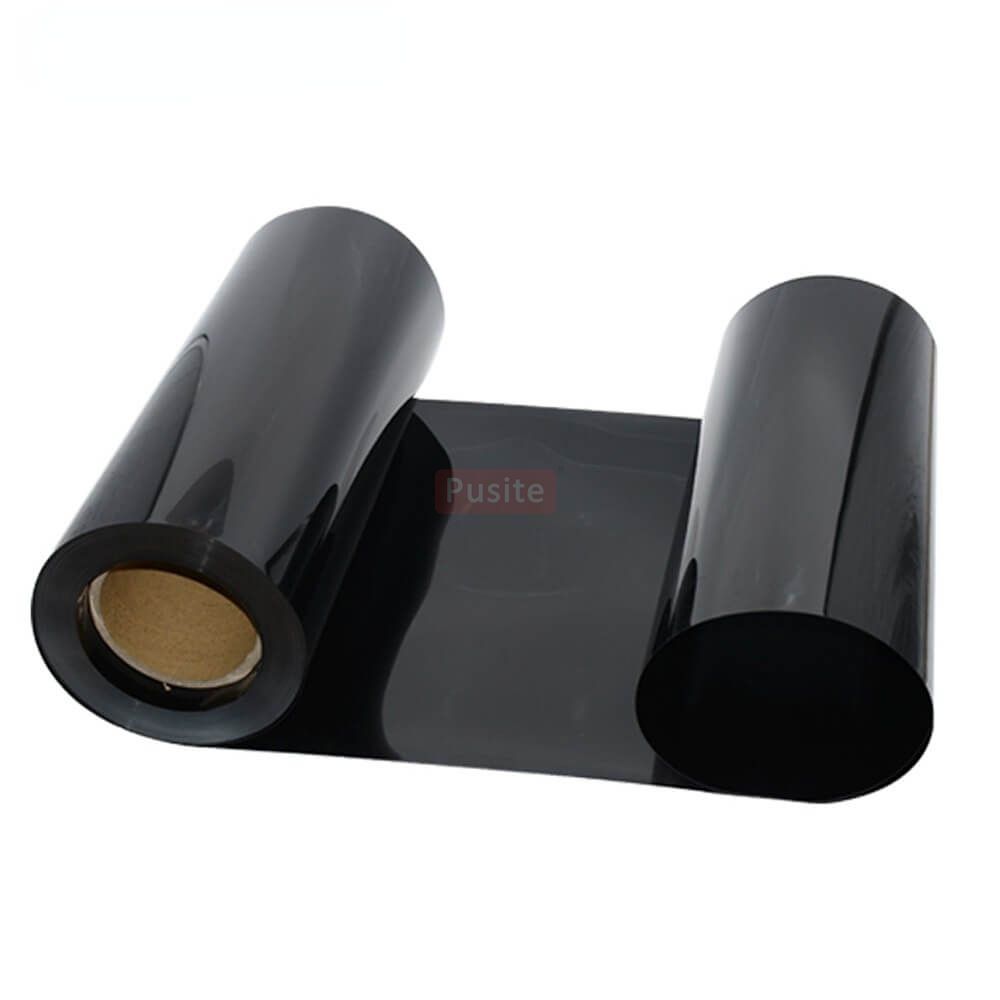

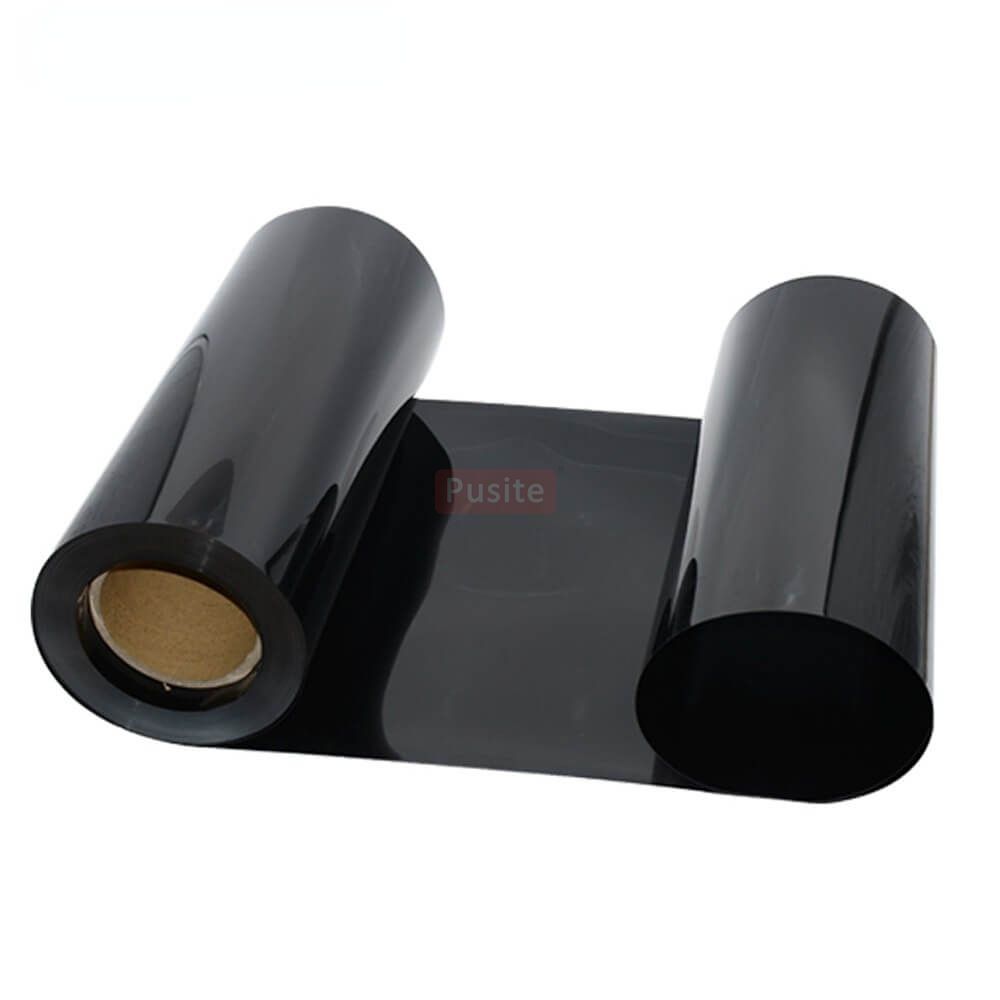

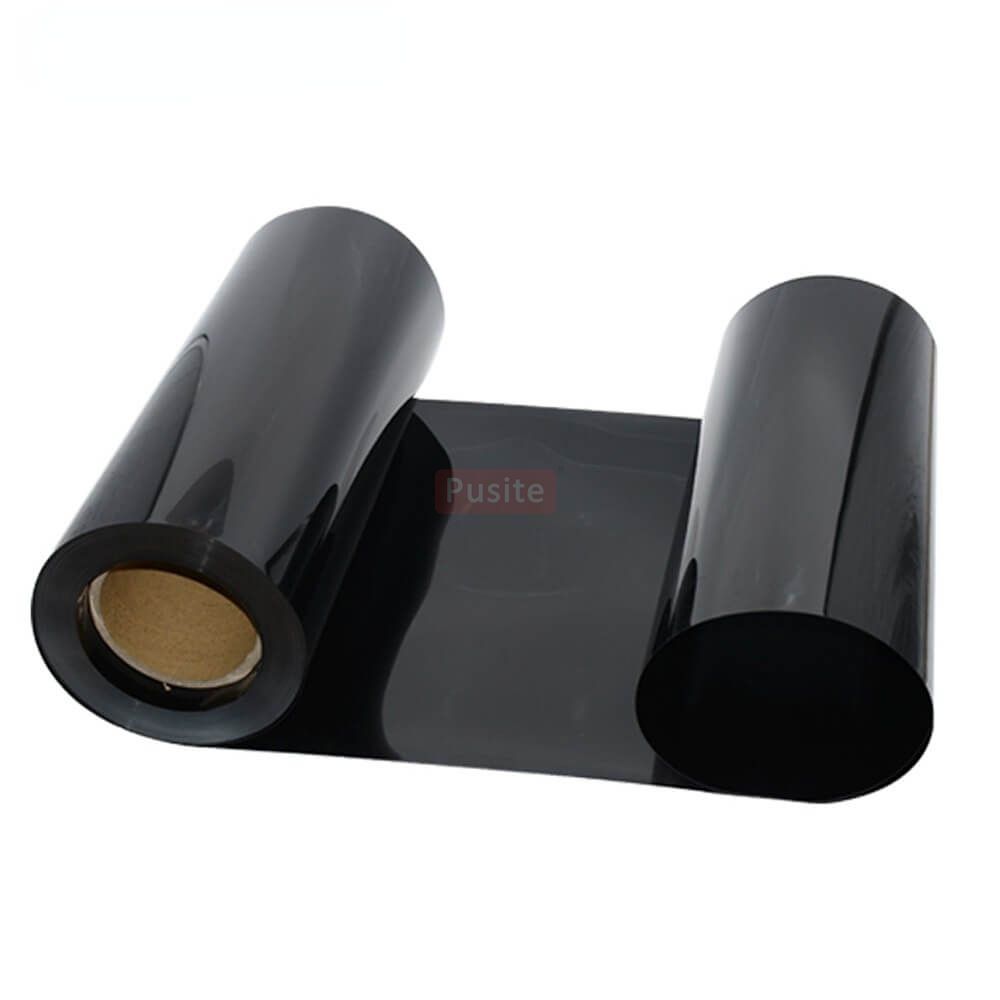

$1.28-$1.92/kgBlack HIPS plastic sheet roll has the characteristics of impact resistance, good processability, smooth surface, recyclable, etc., suitable for the production of various packaging, products and electronic products.

Black HIPS (High Impact Polystyrene) Plastic Sheet Rolls are rolls of plastic sheets made from HIPS material, which is a type of thermoplastic polymer known for its high impact resistance. These rolls come in a black color and are commonly used in various industries for packaging, thermoforming, and other applications.

The black color of these HIPS plastic sheet rolls can be achieved through the addition of pigments or dyes during the manufacturing process. Black HIPS plastic sheet rolls offer several advantages, including:

1. Durability: HIPS material provides good toughness and impact resistance, making it suitable for applications where durability is required.

2. Versatility: These rolls can be easily thermoformed into different shapes and sizes, making them versatile for various packaging and manufacturing needs.

3. Appearance: The black color adds an aesthetic appeal to products, making them suitable for retail packaging where visual presentation is important.

4. UV Resistance: Some formulations of black HIPS plastic sheet rolls may offer UV resistance, making them suitable for outdoor applications where exposure to sunlight is a concern.

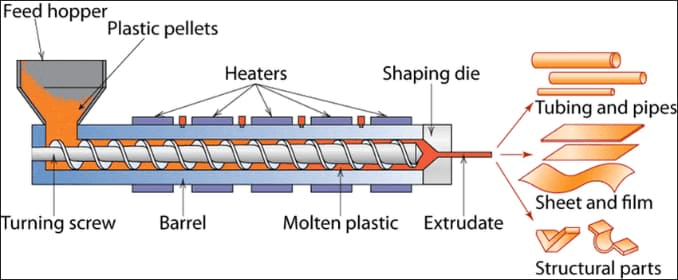

The production process of black HIPS (high impact polystyrene) plastic sheet rolls typically involves several key steps:

1. Raw Material Preparation: The process begins with the selection and preparation of the raw materials. The HIPS resin pellets, as well as any additives such as colorants or UV stabilizers, are carefully measured and mixed to the required specifications.

2. Extrusion: The prepared HIPS resin mixture is then fed into an extruder where it is heated and melted to form a uniform molten mass. The molten plastic is then forced through a die, which shapes it into a continuous sheet of the desired thickness and width.

3. Cooling: After extrusion, the hot plastic sheet passes through a series of cooling rollers or a water bath to quickly cool and solidify. This helps set the dimensions and properties of the sheet.

4. Trimming and Cutting: After the sheet has cooled and solidified, a trimming and cutting process can be performed to remove any irregular edges or excess material and cut it to the desired length or width.

5. Surface Treatment (Optional): Depending on the application requirements, the surface of the HIPS sheet may undergo additional treatments such as corona treatment or coating to improve adhesion, printability, or surface finish.

6. Quality Control: Throughout the production process, quality control measures are implemented to ensure that the HIPS sheets meet the specified standards for thickness, color, surface finish and other characteristics. Finished products are sampled and tested.

7. Winding and Packaging: After the HIPS plastic sheet rolls are inspected and approved, they are wound onto large reels to form plastic sheet rolls. These rolls are then packaged and prepared for shipment to customers or further processing.

Black HIPS (High Impact Polystyrene) plastic sheet rolls have the following unique features:

1. High impact resistance: Black HIPS plastic sheet rolls has excellent impact resistance, able to withstand a certain degree of impact and pressure, thus widely used in packaging and protection.

2. Good processability: Black HIPS plastic sheet roll is easy to process into various shapes through methods such as thermoforming and injection molding, suitable for making products of various sizes and shapes.

3. Smooth surface: Black HIPS plastic sheet rolls typically have smooth surfaces, suitable for printing, laminating, and bonding, resulting in a good appearance.

4. Recyclability: Black HIPS plastic sheet roll is recyclable, contributing to environmental protection and resource recycling.

5. Chemical resistance: Black HIPS plastic sheet roll exhibits good resistance to many chemicals, able to withstand the effects of chemical agents within a certain range.

6. Good electrical properties: Black HIPS plastic sheet roll has good electrical insulation properties, suitable for making housings and insulating components for electronic devices.

1. Electronic product packaging: Black HIPS plastic sheet rolls are used to package electronic products such as mobile phones, tablets, cameras, calculators, etc., providing good protection and beautiful appearance.

2. Household appliance packaging: Black HIPS plastic sheet rolls are suitable for packaging small household appliances such as shavers, hair dryers, blenders, etc.

3. Food packaging: Although the food safety level of the material needs to be confirmed, Black HIPS plastic sheet rolls can be used for outer packaging of certain dry foods or non-direct food contact.

4. Toy packaging: Black HIPS plastic sheet rolls are suitable for blister packaging of various toys, which can well display the products and provide necessary protection.

5. Stationery packaging: For packaging of stationery products such as pens, rulers, scissors, etc., Black HIPS plastic sheet rolls provide sturdy and beautiful packaging solutions.

6. Hardware tool packaging: Blister packaging of hardware products such as small tools, screws, nails, etc.

7. Auto parts packaging: Black HIPS plastic sheet rolls are suitable for packaging of small auto parts such as light bulbs, fuses, car logos, etc.

8. Medical device packaging: Black HIPS plastic sheet rolls can be used for the outer packaging of some non-sterile medical devices such as syringes and thermometers.

|

Product Name |

Black HIPS Plastic Sheet Rolls |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.