Material Composition:

PET plasticPrice Range:

$1.25-$1.89/kg1.8 mm PET plastic sheet offers a balance of strength, transparency, and versatility, making it suitable for a wide range of packaging and other applications.

In the dynamic world of packaging and beyond, finding the perfect balance of strength, transparency, and eco-friendliness is essential. Introducing our 1.8 mm PET plastic sheet – a versatile solution designed to meet your diverse needs while offering exceptional performance and sustainability.

|

A 1.8mm PET plastic sheet refers to a sheet made from Polyethylene Terephthalate (PET) polymer resin, with a thickness of 1.8 millimeters. PET is a type of thermoplastic polymer resin commonly used in various applications due to its favorable properties. Here's a breakdown of what a 1.8mm PET plastic sheet entails:

1. Material: PET (Polyethylene Terephthalate) is a clear, strong, and lightweight plastic resin. It is known for its excellent clarity, high tensile strength, and chemical resistance. 2. Thickness: The thickness of the PET plastic sheet is 1.8 millimeters (or approximately 0.071 inches). This thickness provides a balance between flexibility and stiffness, making it suitable for various applications. 3. Properties:1.8mm PET plastic sheet offers excellent transparency, strength, and versatility. |

1.8 mm PET plastic sheets have some significant advantages that make them ideal for specific applications. Here are some specific advantages of this type of plastic sheet:

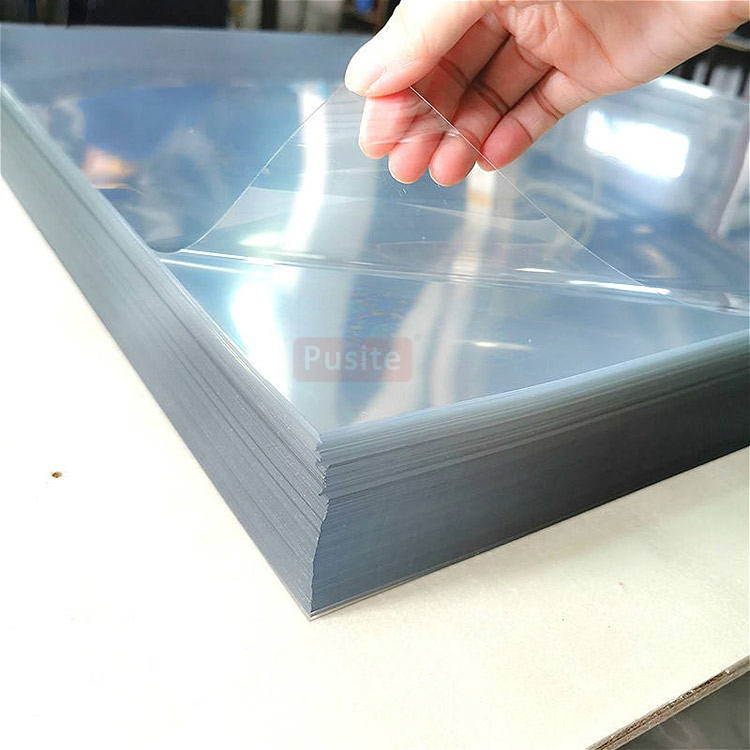

1. Transparency: PET plastic is known for its excellent transparency, which makes it the material of choice in many applications. The 1.8 mm thick PET plastic sheet provides sufficient thickness while maintaining transparency, suitable for applications requiring good visual effects.

2. Lightweight: PET is a lightweight plastic, and a 1.8 mm thick PET plastic sheet is relatively lightweight. This makes it suitable for applications that require overall weight reduction, such as electronic equipment, aerospace fields, etc.

3. Mechanical Properties: PET plastics excel in mechanical properties, including strength and wear resistance. This makes 1.8 mm PET plastic sheets advantageous in some applications that require strength and durability, such as packaging, manufacturing parts, etc.

4. Chemical Resistance: PET is relatively resistant to many chemicals, making it a suitable material for use in chemical environments. This is useful in some applications such as laboratory equipment, chemical containers, etc.

5. Heat resistance: PET plastics generally have good heat resistance and can maintain their properties within a certain temperature range. This makes it useful in applications where high temperature resistance is required.

6. Recyclability: PET is a recyclable plastic, which helps reduce the need for new raw materials and is in line with the environmental protection concept of sustainable development.

7. Multipurpose: Due to its multiple advantages, 1.8 mm PET plastic sheets can be used in many fields, including packaging, printing materials, art products, electronic products, etc.

|

|

|

1. Packaging: 1.8 mm PET plastic sheets are often used for packaging materials such as blister packs, clamshells, and trays due to their transparency and ability to protect products.

2. Graphics: Thin 1.8 mm PET plastic sheets are used in graphic applications, such as printing and signage, where a clear and rigid substrate is needed.

3. Electronics: 1.8 mm PET plastic sheet is used in the manufacturing of electronic components, including flexible printed circuits and displays.

4. DIY Projects: It can be used in DIY projects, crafts, and model making due to its versatility and ease of cutting.

5. Manufacturing Processes: 1.8 mm PET plastic sheets can be produced through processes like extrusion or calendering, where the plastic is melted and then formed into a thin sheet.

|

|

|

|

|

|

| Product name | Clear Pet Sheet 0.5 mm |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

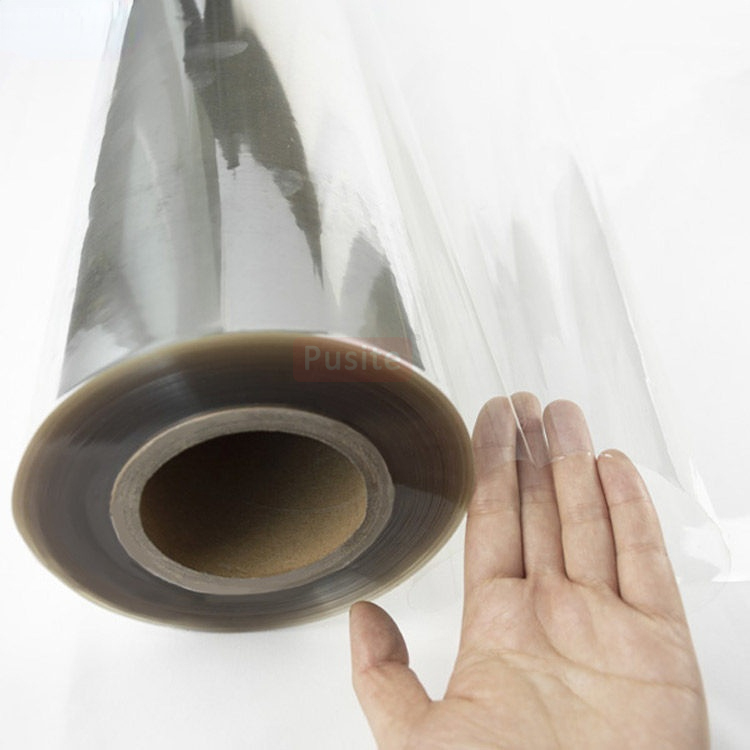

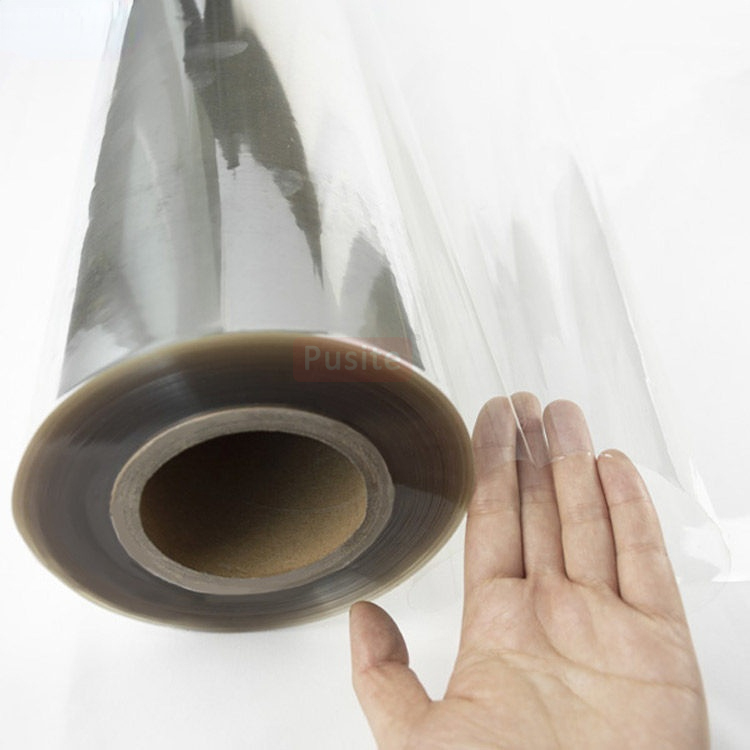

| Shape | Roll/Sheet |

| Thickness | 0.18~2.0mm |

| Width | 300~1400mm |

| Quality | High Quality/Recycled |

| PET Roll Diameter | ≤38 inch |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

Processing PET plastic rolls involves several precautions to ensure safety, quality, and efficiency. Here are some key precautions:

1. Safety Gear: Workers should wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing to prevent injury.

2. Machine Safety: Ensure that all processing equipment is properly maintained and in good working condition. Follow safety procedures for operating machinery, including lockout/tagout procedures when performing maintenance.

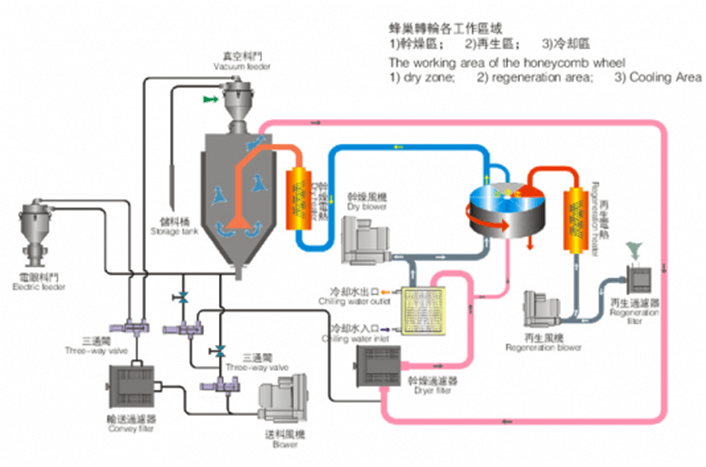

3. Temperature Control: PET plastic is sensitive to temperature variations. Maintain proper heating and cooling conditions during processing to prevent overheating or uneven melting, which can lead to defects in the final product.

4. Dust Control: PET plastic processing can generate dust particles, which can be harmful if inhaled. Implement dust control measures such as ventilation systems and dust collection equipment to minimize exposure.

|

5. Quality Control: Regularly inspect and test the quality of PET plastic rolls during processing to ensure they meet specifications. This includes monitoring for defects such as bubbles, discoloration, or uneven thickness.

6. Handling Procedures: Handle PET plastic rolls with care to avoid damage or contamination. Use appropriate lifting equipment and storage containers to prevent accidents and maintain product integrity. 7. Chemical Safety: PET plastic processing may involve the use of chemicals such as solvents or additives. Follow proper handling and disposal procedures to minimize exposure and environmental impact. 8. Training: Ensure that workers receive adequate training in PET plastic processing techniques, safety procedures, and emergency protocols. 9. Emergency Preparedness: Have procedures in place for responding to accidents, spills, or other emergencies. Provide training and equipment for handling emergencies such as fires or chemical spills. 10. Environmental Considerations: Dispose of waste materials properly and follow regulations for recycling or disposing of PET plastic and other waste products generated during processing. |

|

Product Name |

1.8 mm PET plastic sheet |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.