Material Composition:

PET PlasticPrice Range:

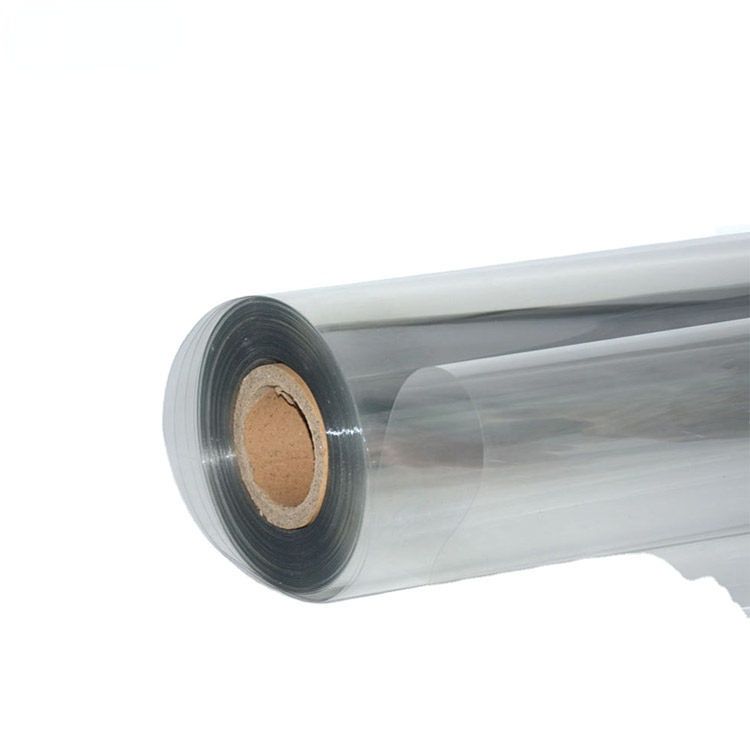

$1.28-$1.92/kg0.5 mm clear thin pet plastic sheet have been widely used in packaging, electronic products, building materials, medical devices and other fields.

0.5 mm clear thin pet plastic sheet is a plastic sheet made of polyethylene terephthalate (PET) material with a thickness of 0.5 mm. PET is a transparent, tough plastic with excellent mechanical properties that is commonly used in a variety of packaging, labeling, electronics and other industrial applications.

0.5mm Clear Thin PET (Polyethylene Terephthalate) Plastic Sheets offer a variety of benefits that make them suitable for a wide range of applications. Here are some of the key benefits:

1. Clarity and Transparency: 0.5mm Clear Thin PET Sheets are known for their excellent optical clarity, making them ideal for product packaging where visibility is a concern.

2. Durability: 0.5mm Clear Thin PET Sheets are a strong and resilient material that is resistant to impact and breakage. This durability ensures a long life for products made from PET sheets.

3. Lightweight: Despite PET's strength, it is lightweight, which helps reduce shipping costs and makes handling easier during manufacturing and assembly.

4. Chemical Resistance: 0.5 mm clear thin pet plastic sheets are resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them suitable for a variety of industrial applications where chemical exposure is a concern.

5. Barrier Properties: 0.5 mm thick clear thin PET sheets has excellent barrier properties to gases and moisture, making it an ideal material for food and beverage packaging as it helps maintain freshness and extend shelf life.

6. Recyclability: 0.5 mm clear thin pet plastic sheet is highly recyclable, which is beneficial to environmental sustainability. Used PET products can be recycled and reused, reducing waste and conserving resources.

7. Thermoformability: 0.5 mm clear thin pet plastic sheets can be easily thermoformed into different shapes and sizes, which is beneficial for customized packaging and product design.

8. UV resistance: 0.5 mm clear thin pet plastic sheets has good resistance to UV radiation, which is suitable for outdoor applications that need to be exposed to sunlight.

9. Cost-effectiveness: Compared to other materials with similar properties, PET sheets are generally cost-effective, providing a balance between performance and cost.

A 0.5 mm clear thin PET plastic sheet offers multiple advantages, making it suitable for various product packaging applications. Here are some common uses:

Food and Beverage Packaging

Plastic Bottles: Used for packaging water, soft drinks, juice, and other beverages.

Food Containers: Such as salad boxes, deli boxes, dessert boxes, keeping food fresh and clearly visible.

Blister Packaging: For individual packaging of snacks, candies, and other small food items.

Cosmetics and Personal Care Products Packaging

Cosmetic Bottles: Such as perfume bottles, lotion bottles, and cream jars.

Skincare Packaging: Such as masks, serums, and facial cleansers.

Pharmaceutical and Medical Supplies Packaging

Medicine Bottles and Blisters: The transparency and chemical resistance of PET materials make them ideal for pharmaceutical packaging.

Medical Device Packaging: Such as syringes, test tubes, and other disposable medical supplies.

Electronics Packaging

Protective Films: Used to protect the screens of mobile phones, tablets, and other electronic devices.

Electronic Component Packaging: The anti-static properties of PET plastic sheet make it suitable for packaging and transporting electronic components.

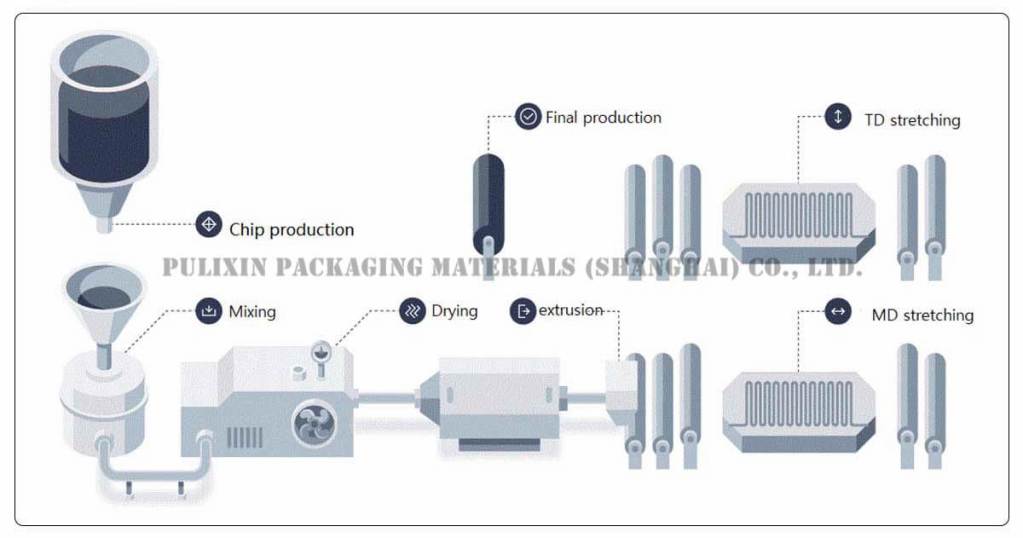

The production process of a 0.5 mm clear thin PET (polyethylene terephthalate) plastic sheet involves several key steps, each crucial to ensuring the final product's quality, clarity, and performance.

Raw Material Preparation

Extrusion

Sheet Formation

Drawing and Stretching

Trimming and Slitting

Quality Control

Packaging and Storage

The production of 0.5 mm clear thin PET plastic sheets involves a series of precise and controlled steps to ensure high quality and consistent properties. From raw material preparation to extrusion, sheet formation, stretching, and quality control, each step is critical to producing a versatile and reliable material suitable for a wide range of applications.

|

Product Name |

0.5 mm clear thin Pet plastic sheet |

|

Material |

PP vacuum forming material , 100% raw material |

|

Color |

Transparent,black,green or any customized color |

| Thickness Tolerance |

According to GB (higher than GB) |

|

Application |

Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

|

Width |

300~1400mm or Customized |

|

Thickness |

0.15~3mm or Customized |

|

Special Treatment |

Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold |

|

Features |

1.High temperature resistance, not easily melted |

|

Sample Time |

1-3 days |

|

Delivery Methods |

Ocean shipping ,air transportation, express,land transportation |

|

Payment Term |

Credit card ,T/T,L/C,Western Union,Paypal |

|

Mass Production Lead Time |

3-15 days depend on order quantity |

|

Certificate |

ROHS,MSDS,TDS,SGS,ISO9001 |

|

Core Diameter |

3 inch or 6 inch depend on customer requirement |

|

Packing |

Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet |

|

Company Profile |

Company Type: Manufacturer |

|

1) Establish Year: 2009 |

|

|

2) Start make export year: 2009 |

|

|

3) Factory area: 6000 square meter |

|

|

4) Patent: Own 39 Product Patents |

|

|

5) Total Empolyees: 50-100 People | |

|

6) Production Line Capacity: 50000 Metric Tons/Year |

|

|

7) No. of Production Lines: Above 10 |

|

|

8) Certifications: Passed the ISO9001:2008 quality system authentication and |

|

|

If you want to find OEM Supplier in China, contact us ! |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you soon.